Technical Information

17

H 408x BM

3. Remove all materials from the oven.

4. Place the oven near the cabinet opening.

5. Ensure that the power is off.

6. Connect the oven to the electrical supply.

7. Set the oven into the cabinet niche, push it all the way in, and align as

necessary.

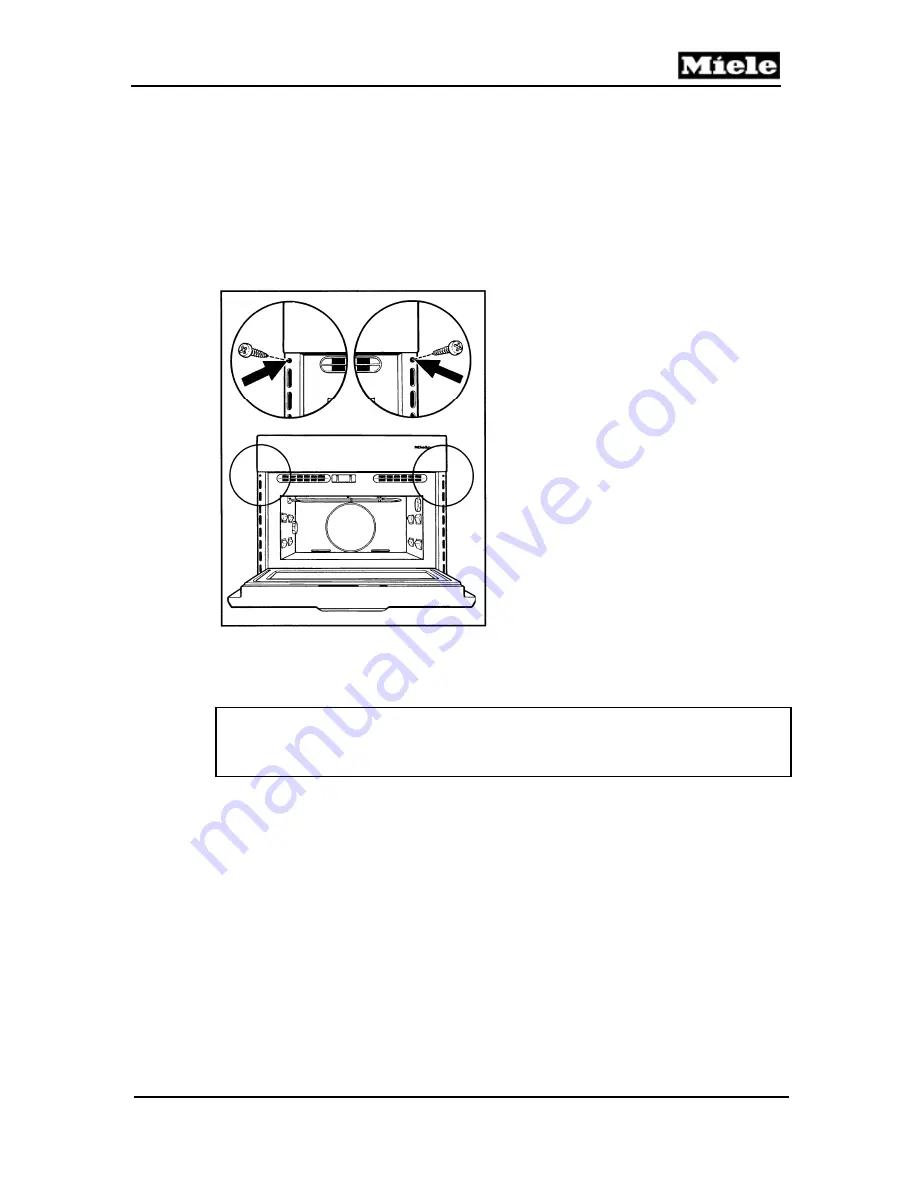

8. Open the oven door and attach the appliance to the cabinets using two

retaining screws at the sides of the frame, as shown in Figure 011-2.

9. Perform “Before Using the Appliance” procedures (refer to Section 011-4.2).

Figure 011-2:

Retaining Screws

4.2

Before Using the Appliance

Note:

The following steps must be performed after performing the installation

procedure (Section 011-4.1).

To ensure proper operation, the following items should be programmed

appropriately for the customer’s needs:

Language

Time of day

Time format (12/24 hour format)

Display clock option

1. Remove the protective film from the front of the appliance (if present).

2. Wipe the interior with a solution of warm water and liquid dishwashing

detergent.

3. Dry with a soft cloth.

4. Leave the door open until the interior is completely dry.

5. Close the oven door.

6. Wash the accessories.

Summary of Contents for H 4080 BM

Page 1: ...TECHNICAL INFORMATION H 408x BM Speed Ovens 2013 Miele USA ...

Page 15: ...Technical Information 15 H 408x BM 011 Casing Door Lock ...

Page 25: ...Technical Information 25 H 408x BM 012 Air Duct Magnetron ...

Page 43: ...Technical Information 43 H 408x BM 020 Door ...

Page 47: ...Technical Information 47 H 408x BM 031 Oven Cavity Wave Distribution ...

Page 52: ...Technical Information 52 H 408x BM 032 Convection Fan Heaters ...

Page 58: ...Technical Information 58 H 408x BM 040 Control Panel Electrical System ...