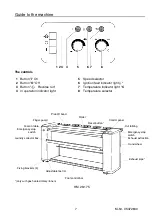

Safety features

Motor protection

If the winding is heated excessively due to

overload the motor is switched off automati-

cally by a winding thermostat. The heater

plate is lowered. Switch the ironer on again

only after it has had time to cool down by

pressing button "I".

Avoid unnecessarily running the ironer

without passing laundry through it.

Do not restrict ironing of smaller articles to

any one part of the roller. Make use of the

whole roller width.

This way an equal amount of heat is obtained

from the heater plate and energy is saved.

The roller is also protected from uneven use.

Safety feature for insufficient air supply*

When there is insufficent air supply to the

machine the heating is automatically switched

off, and the "Ignition fault" indicator light

comes on.

It is only possible to iron cold after a few

minutes.

Check whether the exhaust system is clear.

If there is nothing wrong with the exhaust sy-

stem call the Service department.

Safety feature for insufficient gas supply*

When the gas stopcock is turned off or the

gas supply pressure is low, the rotary iron can

not be switched on. If the gas supply pressure

is reduced during operation, the machine swit-

ches off automatically and the heater plate is

withdrawn.

When the gas supply pressure has been re-

established, the machine can be switched on

again by pressing the "I" button.

If this fault recurs the on-site gas supply

system must be checked by an accredited

gas engineer, (Corgi registered in the UK).

*) only with gas heated rotary ironers

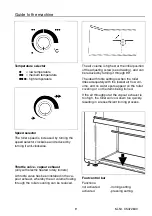

Emergency release during a power cut

There is a handwheel at the rear of the right

hand column which can be operated manually

to release the roller from the hot heater plate

in the event of a power cut. Isolate the ma-

chine from the electricity supply. Turn the

handwheel anti-clockwise to lower the heater

plate from the roller. During normal operation

the wheel turns as the heater plate is brought

into position or withdrawn.

M.-Nr. 05372840

14