Installation

The rotary ironer may only be commis-

sioned by the Miele Service Department or

a Miele authorised Dealer.

This machine must not be installed in the

same room as dry cleaning machines using

perchlorethylene (PER) or Chlorofluorocar-

bons (CFCs). On combustion, the escaping

vapours are decomposed to form hydrochloric

acid which can result in dangerous conse-

quences.

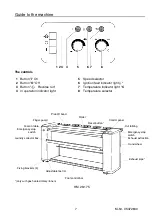

Transportation to installation site

The machine should be transported on its

wooden base to the site where it will be instal-

led. Only then should it be taken off the

wooden base.

Lifting points for lifting gear such as straps

and hooks are located underneath the side

base frames of the machine stands near the

feet.

When setting up the machine leave at least

400 mm space each side of the machine so

that the side panels are accessible.

Removing the transit fitting.

Remove the transit fitting at the rear of the ma-

chine. This is not applicable to gas-heated rot-

ary ironers.

Levelling and securing the ironer

The machine must be level both lengthwise

and widthwise. Use a spirit level and adjust

the feet if necessary (use a SW = 19 mm

spanner).

When adjusting the feet loosen the locking

nuts on the fixing bracket, make the adjust-

ment then tighten the locking nuts back

against the casing.

The ironer should be secured to the floor

using the screws and dowels supplied with

the machine. The holes for the dowels should

be drilled through the holes in the

fixing bracket, (see installation diagram). After

tightening the floor fixing bolts tighten the nuts

which fix the bracket to the machine base.

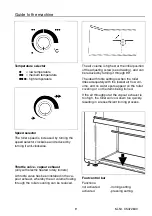

Attaching the work table

The two support brackets for the work table

on the inside of the end stands should be

secured with the M 8 screws supplied.

The separately provided work table is laid on

top of the brackets, levelled so that the gap

between the feed out edge of the roller and

the work table is as small as possible, and

secured with the wood screws provided.

21

M.-Nr. 05372840