Opening and closing the door

30

Opening the door using the emergency release

The emergency release may only be used when it is no longer

possible to open the door normally, e.g. in the event of a power

cut.

If the emergency release is operated during a programme cycle,

hot water and cleaning agents can escape.

Risk of scalding, burning and chemical burns.

Push against the door so that less force is needed to operate the

emergency release.

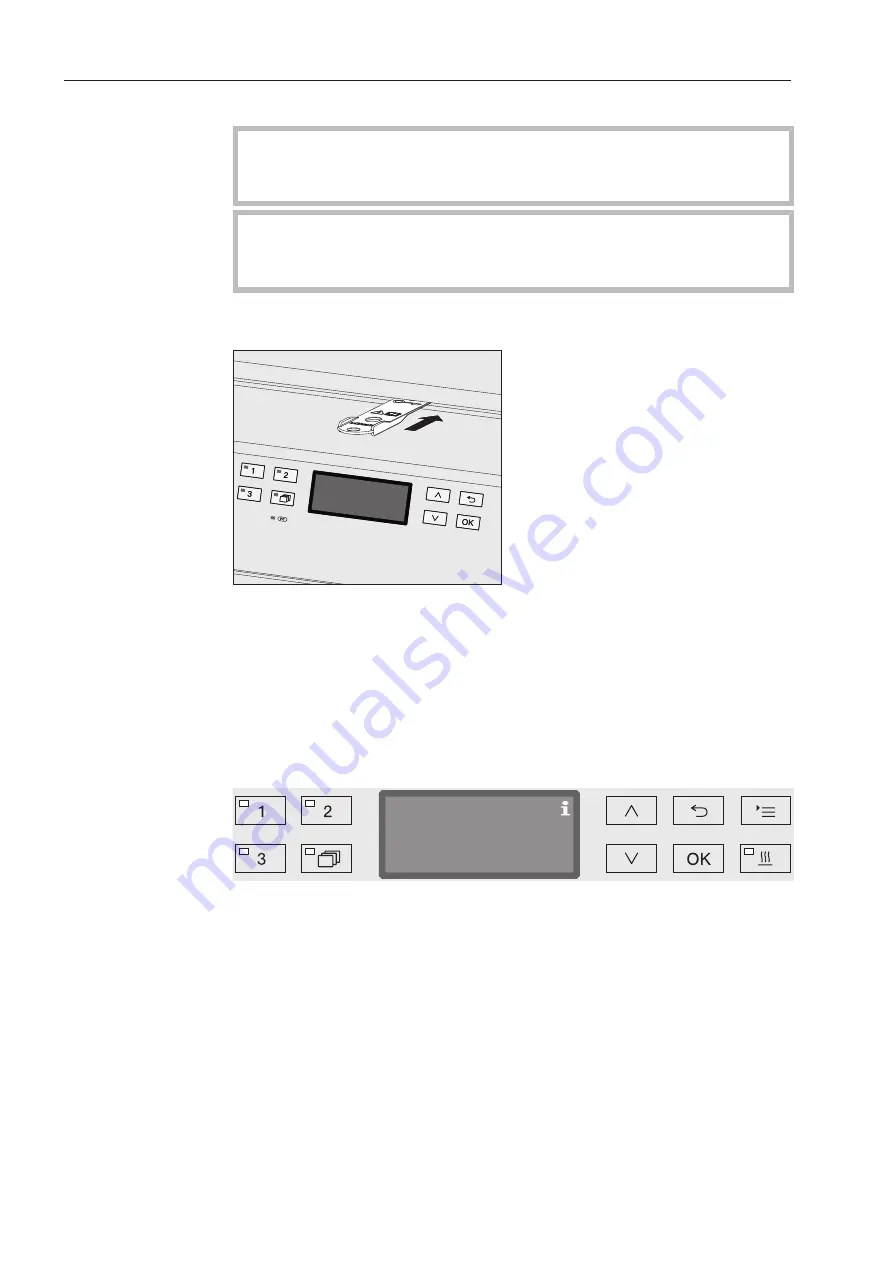

Push the tool supplied in the accessory pack horizontally into the

gap between the door and the lid or worktop. The right hand edge

of the tool must align with the outer right hand edge of the display.

Press against the unlocking mechanism with the tool until you hear

the door unlock. The door can now be opened.

If the washer-disinfector is switched on, activation of the emergency

release will be recorded in the process documentation and the

following message will appear in the display:

Emergency release

The message remains in the display until the door is closed. It is not

recorded if the machine is switched off.