Drain pump

Max. temperature

203

°F

95

°C

Drain hose (int. diameter)

7/8

''

22 [DN 22] mm

On-site hose connector for drain hose

(int. diameter x length)

7/8

''

x 1 3/16

''

22

x

30 mm

Max. transient throughput

6.9 gal/min

26 l/min

Drain pump head height (from floor level)

39 3/8”

1000 mm

Vented drainage required. If ventilation is insufficient, fit Miele

kit, Mat. no. 05238090.

Drain manifolds serving several machines must be of suffi-

cient cross-section.

Dump valve

Max. temperature

203

°F

95

°C

Machine-side drain connection (ext. diameter)

2 15/16

''

75 [DN 70] mm

On-site drain (int. diameter)

2 15/16

''

75 [DN 70] mm

Max. transient throughput

16.4 gal/min

62 l/min

Vented drainage required. If ventilation is insufficient, fit Miele

kit, Mat. no. 05238090.

Drain manifolds serving several machines must be of suffi-

cient cross-section.

Fittings for base

/ floor installa-

tion

Miele base UG/UO 6008

4 × metal angled brackets

(to secure machine to base)

4 × screws DIN 571 (Ø × length)

5/16

''

x 2 9/16

''

8 x 65 mm

4 × rawl plugs (Ø × length)

1/2''

x

2 3/8“

12 x 60 mm

Base must be bolted to the floor. Machine must be fixed to the

base.

Fixing materials for a floating screed floor are to be provided

on site.

Miele US 6008 base

4 × metal angled brackets

(to secure machine to base)

4 × screws DIN 571 (Ø × length)

4 × rawl plugs (Ø × length)

1/4''

x 2“ 6

mm x

50 mm

5/16

''

x 1 9/16

''

8

mm x

40 mm

Base must be bolted to the floor. Machine must be fixed to the

base.

Fixing materials for a floating screed floor are to be provided

on site.

Installation on floor or concrete base

2 × clamps

2 × screws DIN 571 (Ø × length)

2 × rawl plugs (Ø × length)

1/4''

x 2

''

6

mm x

50 mm

5/16

''

x 1 9/16

''

8

mm x

40 mm

Machine must be bolted to the base or floor. Fittings are

supplied with machine.

Fixing materials for a floating screed floor are to be provided

on site.

Machine data

Unit width

27 9/16

''

700 mm

28 5/8

''

727 mm

40 3/16

''

1020 mm

27 1/4

''

692 mm

Unit

depth

Unit height

Casing width

Casing depth

27 3/16

''

690 mm

Minimum width of delivery access to installation site

28 3/8

''

720 mm

1100 mm

Recommended rear wall gap (measured to front of machine) 43 5/16

''

Minimum rear wall gap (to front of machine)

35 7/16

''

Recommended rear wall gap ensures sufficient space for

maintenance and servicing.

900 mm

Net weight

309 lbs

140 kg

Dynamic floor load, max.

2600 N

2600 N

Static floor load, max.

1850 N

1850 N

Dynamic load, max.

750 N

750 N

Drum frequency, max.

22 Hz

22 Hz

Average heat dissipation

(dependent on ambient room temperature and

program selected)

2830 BTU/hr

0.83 kWh

Sound pressure (re 20 mPA),

workplace-related (at distance of 1 m and height of 1.6 m)

<70 dB (A)

<70 dB (A)

Installation should only be carried out by authorized

installe

rs in accordance with valid regulations! Observe installation

instructions when installing machine! All rights reserved!

Technical datasheet: PW 6080 LP/AV

Date:

2015-

Sep

-

02

Page: 1

5

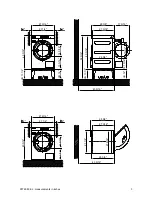

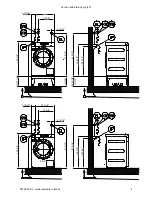

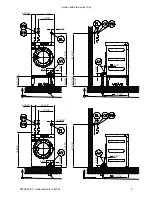

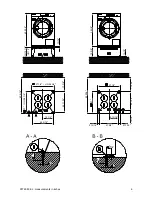

Summary of Contents for PW 6080 EL

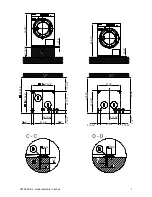

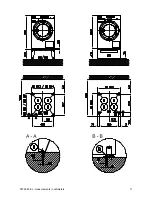

Page 8: ...PW 6080 EL measurements in millimeters 8 ...

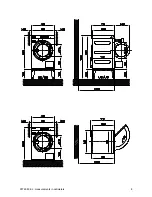

Page 9: ... Version with drain pump LP PW 6080 EL measurements in millimeters 9 ...

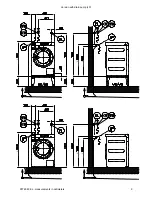

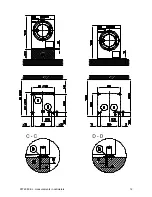

Page 10: ...Version with drain valve AV PW 6080 EL measurements in millimeters 10 ...

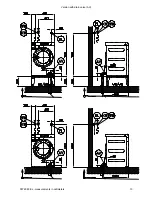

Page 11: ...PW 6080 EL measurements in millimeters 11 ...