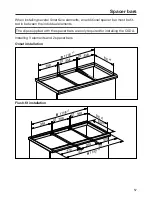

Spacer bars

57

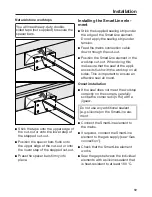

When installing several SmartLine elements, an additional spacer bar must be fit-

ted in between the individual elements.

The clips supplied with the spacer bars are only required for installing the CSDA.

Installing 3 elements and 2 spacer bars

Onset installation

Flush-fit installation

Summary of Contents for SmartLine CS 7632

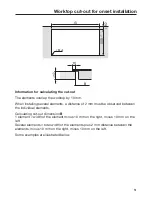

Page 49: ...Building in dimensions 49 Onset installation a Front b Mains connection cable L 2000 mm ...

Page 64: ......

Page 65: ......

Page 66: ......