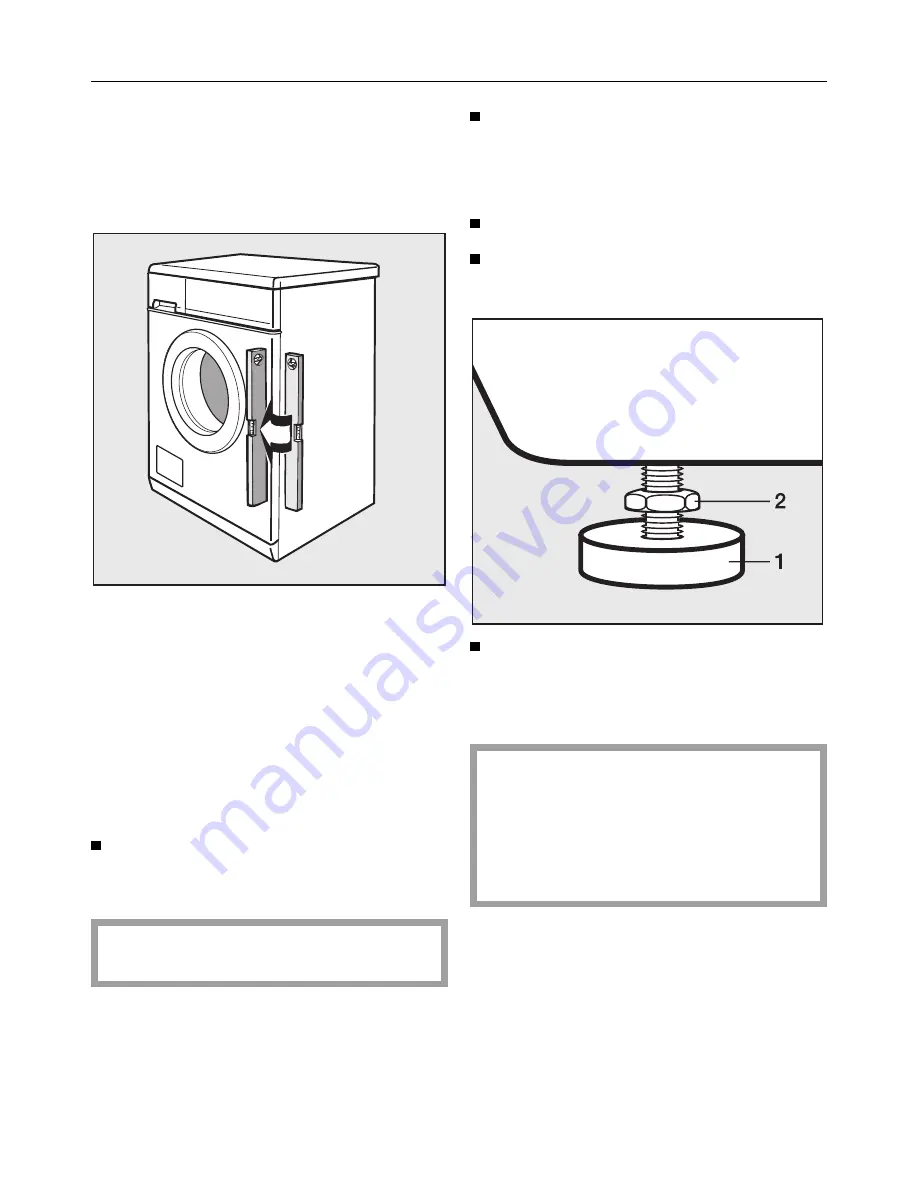

Levelling the machine

The machine must stand perfectly level

on all four feet to ensure safe and

proper operation.

Incorrect installation may increase elec-

tricity and water consumption and may

cause the machine to move about.

The four adjustable screw feet are

used to level the machine. All four feet

are screwed in when the machine is de-

livered.

Screwing out and adjusting the feet

Gently tip the machine and prop it

up using a solid wood wedge for

example, to ensure stability.

Make sure the machine does not

slip as this could cause injury.

Loosen counter nut

2

with a spanner

by turning it anti-clockwise, then turn

foot

1

together with the counternut

and unscrew.

Put the machine back on all four feet.

Use a spirit level to check the ma-

chine is standing level.

Hold the foot

1

firm using a pipe

wrench and using a spanner turn the

counternut

2

to the right firmly up

against the housing.

All four counternuts must be firmly

up against the housing. Please also

check this for the feet which did not

need adjustment. Otherwise there is

the danger of the machine moving

about.

Installation and connection

56