Plumbing

Connection to water supply

Fitting

The machine should be connected to a

mains water supply in accordance with

standard regulations. The German auth-

orities do not require it to have a non-re-

turn valve as the washing machine has

been designed to comply with DVGW

regulations (German Association of

Gas and Water Engineers, see data

plate).

The machine is designed to operate

with a minumum water pressure of 1

bar. There is a minimum flow pressure

of 1 bar pressure if 5 litres of water flow

into a suitable container in 15 seconds.

The water pressure must not exceed 10

bar.

If the water pressure is higher than 10

bar it is essential to fit a reducer valve.

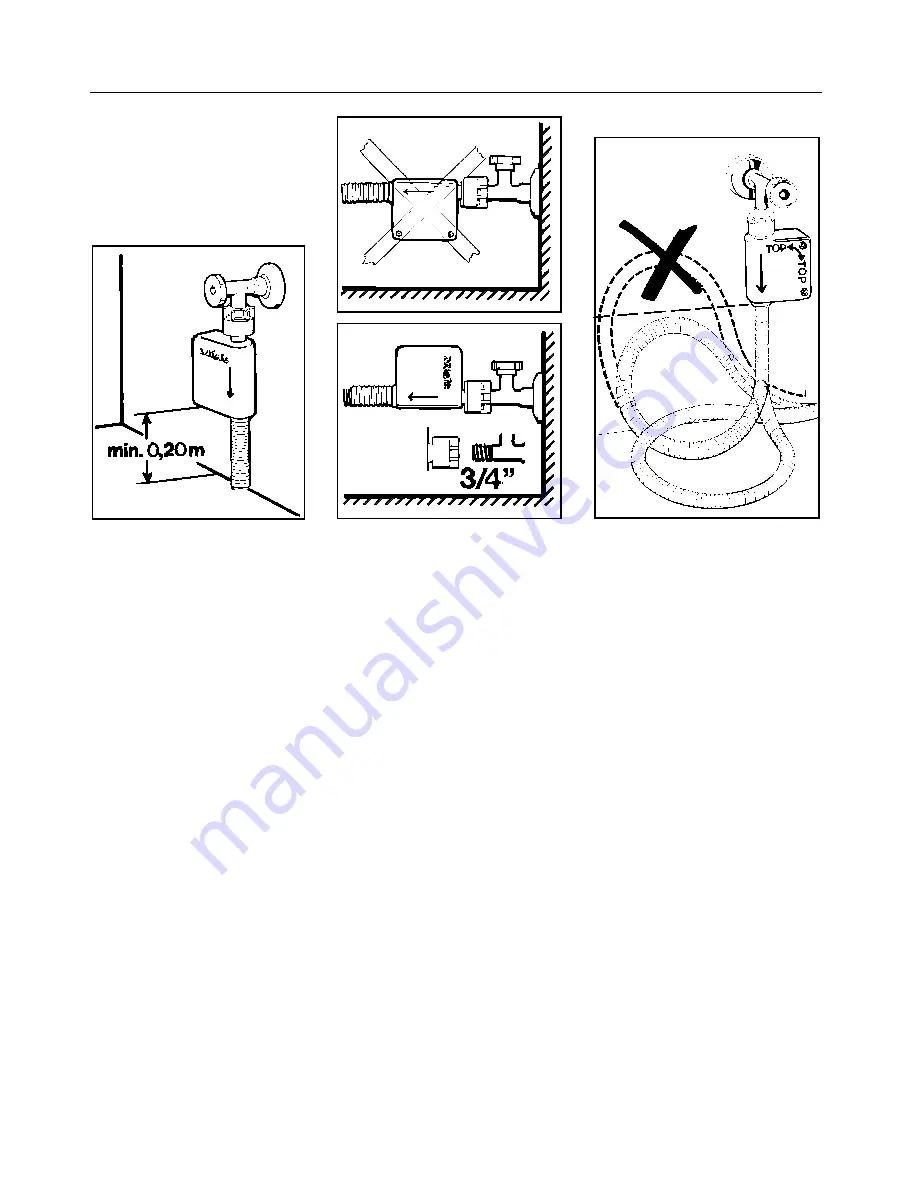

The

Miele "Waterproof system"

con-

nected between the stopcock and the

machine offers the safest protection

against water leaks.

For the "Waterproof system" to function

correctly, it may only be fitted in the po-

sitions shown (see illustrations above).

Connection to the mains water supply

should incorporate a mains stopcock

with 3/4" thread. The stopcock should

be fitted by a qualified plumber.

37