Operators Manual

15

2.1 DC TIG welding

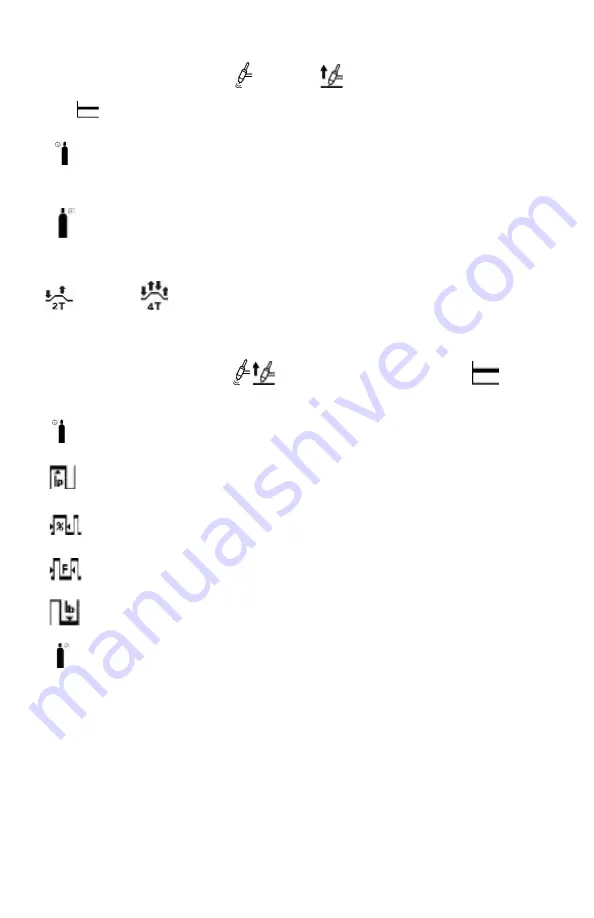

Set the (Welding mode knob) to “

HF ignition

lift arc” and (AC/DC transfer knob) to

DC“

” , would enter into DC TIG welding mode. In this mode to adjust by “Parameter

knob” ”Parameter positive knob”:

(

) to adjust the Pre-flow time

( Ic ) to adjust the welding current;

(

) to adjust the stopping gas delay time;

Choose (2step, 4step switch) set on different gears to choose the welding method “2 step ”

“four step

(See the details introduction is “Technical Instruction”)

2.2 DC pulse TIG welding

Set (Welding mode knob)to “TIG

” , (AC/DC transfer knob) to “DC

” , (Pulse

switch) set on “Pulse” would enter into the by “Parameter knob” ”Parameter positive knob”:

(

) to adjust the Pre-flow time;

(

) to adjust the pulse peak current;

(

) to adjust the Pulse width;

(

) to adjust the Pulse frequency;

(

) to adjust the Pulse Background current;

(

) to adjust the stopping gas delay time;

2.3 Trigger Mode Control Button (HF TIG and LIFT TIG Mode only)

The trigger mode control is used to switch the functionality of the torch trigger between 2T

(normal), and 4T (latch mode).

2.3.1 Remote Control Operation

When the remote control terminal is connected, you adjust the middle knob on front panel

to set the max value of remote control (Eg. If you set it as 150A, the max value you can reach

by remote torch will be 150A). After you finish the setting for 5s, the front display will show

the real output set by the remote torch.