Migomag ACDC 200

Model No MOMACDC

16

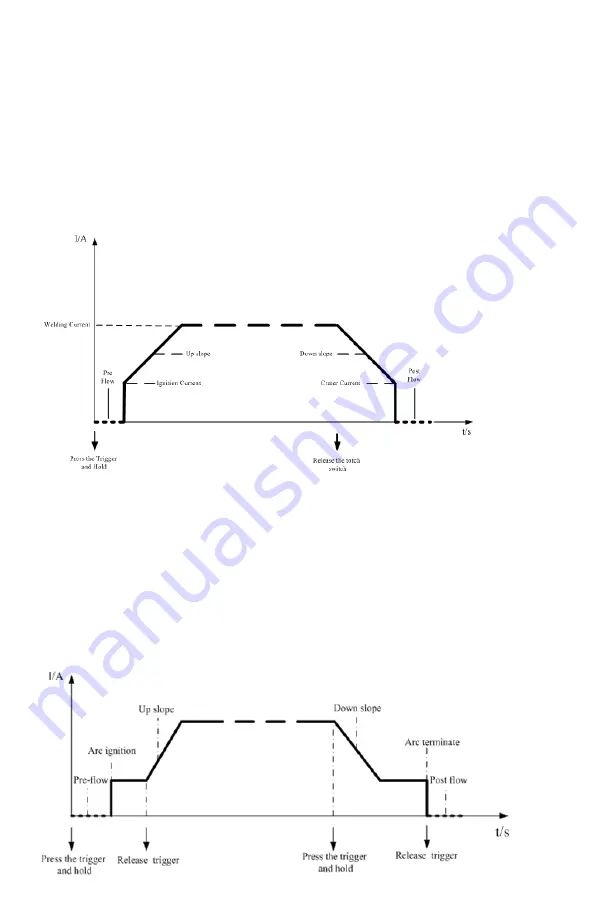

2.3.2 2T Normal Mode

In this mode, the torch trigger must remain depressed for the welding output to be active.

Press and hold the torch trigger for Ignition in the 2T mode, there is the function for up slope

and down slope function it is set by timer on the function panel of the machine by the arrow

buttons by scrolling (5 on page 10) to the up slope light when it is laminated on the panel

then you can adjust by item (6 on page 10) time is from 0-15sec when you want to set the

down slope time, it’s the same pushing the arrow button until the light is laminated on down

slope and use item (6 on page 10) to set the time it’s from 0-15 sec.

When welding the up slope will weld for the time set and for down slope time will run from

when your release the trigger on the torch. After you finishing welding the down slope time

will start until the time period is finished and then if post gas will run for the time set and

then the welding arc will stop welding.

2.3.2 4T Latch Mode

This mode of welding is mainly used for long welding runs to reduce operator fatigue. In this

mode the operator can press and release the torch trigger and the output will remain active.

To deactivate the power source, the trigger switch must again be depressed and realized,

thus eliminating the need for the operator to hold the torch trigger.

Note that when operating in GTAW (HF and LIFT TIG modes), the power source will remain

activated until the selected down slope time has elapsed.

NOTE: This Up Slope operates in (4T) TIG modes only and is used to set the time for the weld

current to ramp up, after the torch trigger switch has been pressed then released, from

Initial Current to High or BASE current.