6x

M3x10

1x

M3x3

M2,5x10

4x

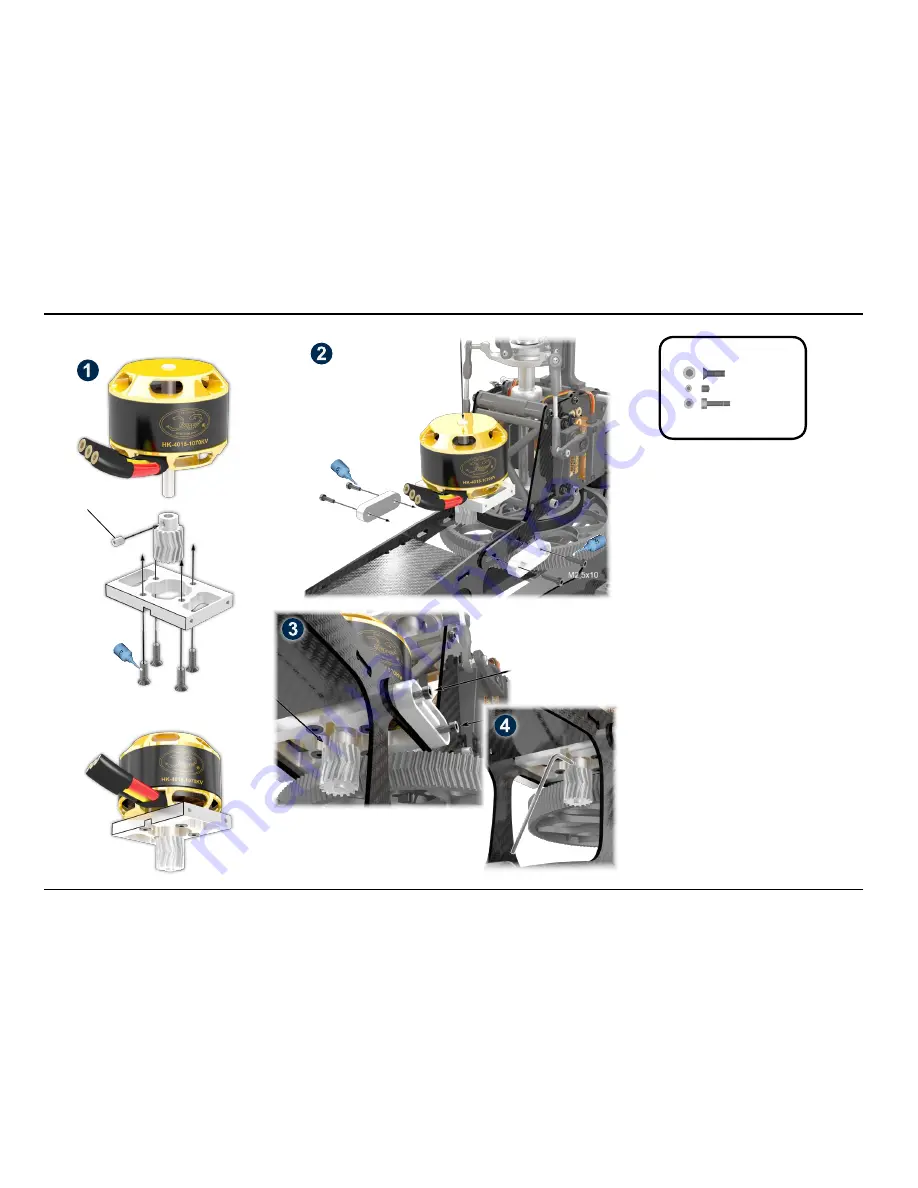

Installation of Motor and Gear Mesh

1) Mount the motor as shown in image (1), using the four

countersunk screws M3x10. Make sure that the M3x3 set

screw is placed at the flattened area of the motor shaft. Do

not fasten the set screw now (it can only be used once!)

- the pinion will be positioned later.

2) Mount the motor plate, as shown in (2), using the four

set screws M2.5x10 and the additional aluminum braces.

Do not tighten the screws completely, as the entire motor

plate should be still moveable.

3) Push the motor with pinion as close to the main gear as

possible, see image (3). The centers of the herringbone of

pinion and main gear must be aligned exactly. The main

gear has a slight axial play for easy adjustment.

4) Now fix the pinion to its final position by tightening the

M3x3 set screw. This set screw can only be used once.

You must secure it by using thread lock!

5) Pinion and main gear should have minimal gear mesh.

The main gear is not 100 % round (due to the free wheel

unit). Therefore there will be a small area without any

gear mesh. This is normal. Do not use paper for setting

the gear mesh (this does not work with the herringbone

gear!). Now secure the M2.5 socket head cap screw with

thread lock.

6) During pre-flight check, before each flight, the gear

backlash must be checked! Also, the gear must be che-

cked for wear and tear. If necessary, adjust the gear mesh

and/or replace the gears. Note that the motor ball bearing

can also be subject to wear and tear, as well as to excess

play.

Bag 6

Do not tighten yet!

Manual LOGO 480 - ©Mikado Model Helicopters GmbH -2013- Page 12

10 Motor Installation

Bag 6

M2,5x10

M3x10

M2,5x10