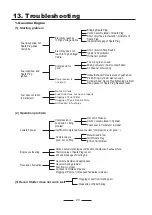

1. Gasoline Engine

(1) Starting problem

Fuel is supplied, but

Spark Plug does

not ignite

Electricity reaches

to High Voltage Cable

Electricity does not

reach to High Voltage

Cable

Bridging Spark Plug

Carbon accumulated on Spark Plug

Short circuit due to insulation problems of

Spark Plug

Inappropriate gap of Spark Plug

Short circuit of Stop Switch

Ignition coil problems

Oil Sensor problem

The wrong fuel is used

Mixing of water or dust contamination

Air Cleaner not working

Intake/Exhaust Valve is stuck or pushed up

Piston Ring, Cylinder wear enough

Cylinder head, Spark Plug tightening problem

Head gasket or Spark Plug Gasket breaks

Dirt of Air Cleaner

Carbon accumulated in Cylinder.

Fuel Level in Carburetor inproper

Compression is

good

Compression is

not good

No fuel in tank

Fuel Cock does not open properly

Clogging of Fuel Filter

Clogging of Tank Cap Air Hole

Air trapped in fuel pipe

Fuel supplied, and

Spark Plug

ignites

Fuel does not reach

to Carburetor

(2) Operation problem

Compression is

good and no firing

problem

Insufficient compression (see the item “compression is not good.” )

Compression is

good, but no firing

Water mixed in fuel

Dirt of Spark Plug

Ignition Coil problem

Lowered power

Engine overheating

Carbon accumulated inside combustion chamber and exhaust hole.

Thermal value of Spark Plug is poor

Dirt and breakage of Cooling Fin

Revolution fluctuation

Governor adjustment inappropriate

Governor Spring problem

Fuel flows in proper

Air taken from Intake Pipe line

Clogging of Pilot Jet ( Idle speed fluctuates improper)

(3) Recoil Starter does not work well

Clogging of dust from rotating part

Weakening of Spiral Spring

20

13. Troubleshooting

Summary of Contents for MVC-88GE VAS

Page 4: ......

Page 14: ...SSHDUDQFH 8 2YHUDOO LPHQVLRQV 8 8 4 8 5 8 5...

Page 28: ...402 03019 10 08 00 BSC...