15

For MT-55 / 55L / 65H

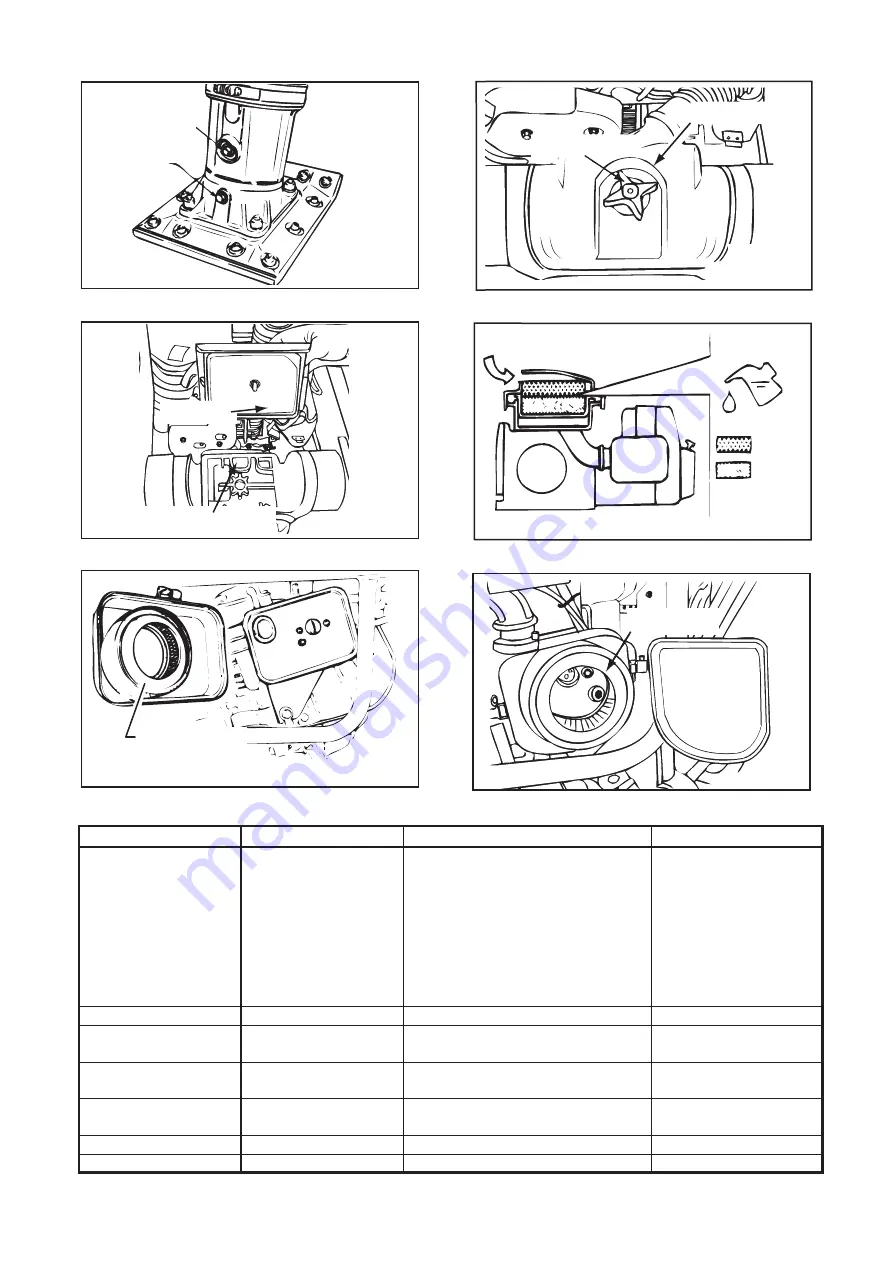

Air Cleaner

Bolt, Cover

Fig.11

All models

Oil Level Gauge

Drain Plug

Fig.10

Table of scheduled checks

Engine oil

Every 2 years

Fuel hose

Replace

How often?

Place to check

Item to check

Oil etc.

Daily

(before starting

operation)

Appearance

Air cleaner

Bolts, nuts

Handle

Rubber damper

Engine oil

Fuel tank

Fuel system

Flaws, deformity, stains

Dirt, flaws, deformation

Loose or missing parts

Flaws, deformity, cracks, breaks

Flaws, deformity, cracks, breaks

Leaks, fuel level,presence of dirt

Leaks, wear, loose parts

Engine oil

Engine oil

Gasoline

After first 20 hours

Engine oil

Replace once, after the first 20 hours

Engine oil

Every 50 hours

Spark plug

Clean, adjust gap

Replace

Engine oil

Every 200 hours

Replace

Engine oil

Leaks,oil level,dirt

Leaks,oil level,dirt

Primary element

Every 80 to 100 hours

Cleaning

Lamp kerosene

Secondary element

Every 100 to 150 hours

Cleaning

Neutral detergent

Engine oil(25-30cc)

(water washing and dry)

Main body lubrication oil

Main body lubrication oil

For MT-72FW / 72FWA / 84F

SAE30

2

㹼FF

13

㹼FF

Fig.13

For MT-55 / 55L / 65H

Fig.12

Bleather Filter

Element

For MT-72FW / 72FWA / 84F

Fig.14

Air Cleaner

For MT-55 / 55L

Fig.15

Element