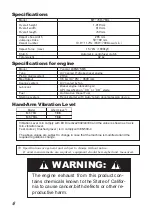

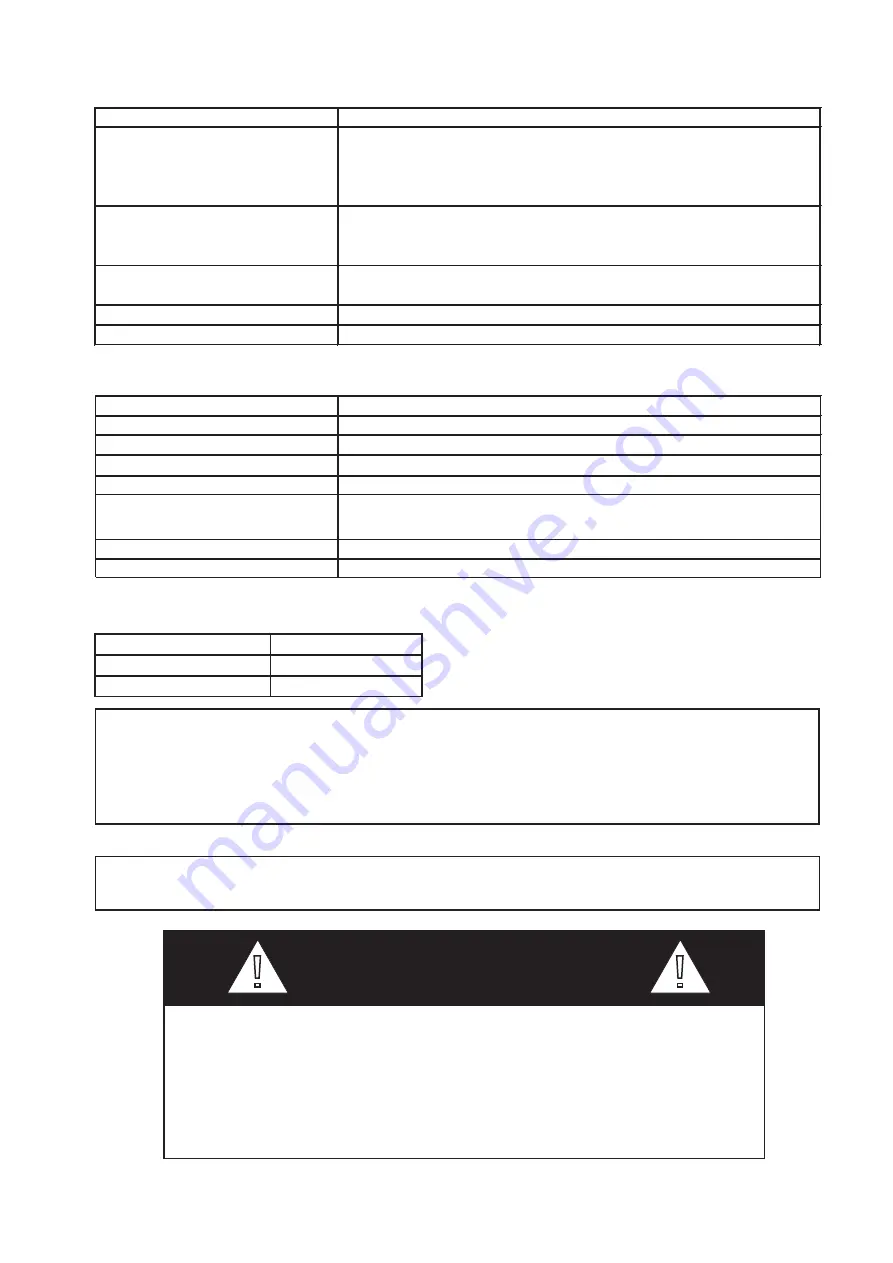

Specifications

Specifications for engine

6

Model

MT-76D/76DL

Overall height

1,010 mm

Overall width

410 mm

Overall length

740 mm

Impact shoe width

285 mm

Impact number

(650

~

700blows/min.)

10.8~11.7Hz

Impact force (max.)

15.7kN (1,600kgf)

Clutch

Automatic centrifugal clutch

Total weight

82 kg

Model

Yanmar L48N6-SMK

Type

Air-cooled 4-stroke diesel engine

Piston displacement

219cc

Max.Output

3.5 kw (4.7 PS) / 3600 rpm

Cooling system

Air-cooled by fan

Lubricant

Diesel engine lubricating oil

API classification "CC" or "CD" grade

Fuel

Automotive Diesel Fuel

Starting system

Recoil starter with Auto-return decompression device

Jumping stroke

50~80 mm

!

!

WARNING:

The engine exhaust from this product con-

tains chemicals known to the State of Califor-

nia to cause cancer,birth defects or other re-

productive harm.

Vibration Level is in comply with EU Directive2002/44/EC and the value is shown as 3 axix

min. vibration level.

Test course ( Crushed gravel ) is in comply with EN500-4.

The above values are subject to change in case that the machine is modified or/and the

required regulations change.

※

Specifications are general and subject to change without notice.

If exact measurements are required, equipment should be weighed and measured.

Model

A

h

v

(m/sec

2

)

MT-76D

MT-76DL

18.5

16.8

Hand-Arm Vibration Level

Summary of Contents for MT-76D

Page 2: ......

Page 18: ...Note...

Page 19: ......

Page 20: ...PRINTED IN JAPAN MIKASA SANGYO CO LTD 1 4 3 Sarugakucho Chiyoda ku Tokyo 101 0064 Japan...