10

TEMPERATURE

CLASSIFICATION OF OIL

20

°

C (+68

°

F)or over

SAE 30

10

°

C(+14

°

F) - 20

°

C(+68

°

F)

SAE 20

B elow1 0

°

C(+14

°

F)

CC class or high er grade

SAE 10W - 30

!

!

!

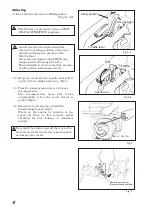

Fig.7

Fuel tank

Fuel filter

7.Service

CAUTION:

Flammable Liquid. When refueling, stop engine and

allow it to cool. Do not smoke or allow work to be

performed in the immediate area. Fire or explosion

could result from flames or sparks, or if fuel is spilled

on a hot engine.

Moving Parts. Shut down the engine before performing

service or maintenance functions.

Contact with moving parts can cause serious injury.

High Temperatures. Allow machine and engine to cool

before performing service or maintenance functions.

Contact with hot components can cause serious

burns.

7 - 1 DAILY

* Thoroughly remove dirt and oil from the engine

and control area.

* Clean or replace air cleaner as necessary.

* Check and retighten all fasteners as necessary.

* Check spring box and bellows for oil leaks.

Repair as needed.

* Remove element from pre - cleaner at the top of

crankcase(body side) and clean it by air.

7 - 2 WEEKLY(every 50 hours)

* Remove the fuel filter cap and inspect clean fuel

tank.(Fig.7)

7 - 3 Replacement of Lubricant(BODY)

* Remove the drain plug at the rea r of tamper foot

and drain dirty oil. Refill with clean oil to the

middle of the sight glass. Oil bath contains

approx. 1.7 pt. (800 cc) for MT - 76D.

INITIAL OIL CHANGE:

After 50 hours of operation

SECOND OIL CHANGE AND/OR LATER:

Every 200 hours of operation

7 - 4 Replacement of Lubricant(ENGlNE)

7 - 4 - 1 While the engine is still warm, remove the

drain plug. For quick discharging, it is

advisable to take off the oil gauge.

Replace drain plug and refill engine

crankcase.(Fig.8)

7 - 4 - 2 Refer t he following chart, for oil types.

Drain plug

Fig.8

Summary of Contents for MT-76D

Page 2: ......

Page 18: ...Note...

Page 19: ......

Page 20: ...PRINTED IN JAPAN MIKASA SANGYO CO LTD 1 4 3 Sarugakucho Chiyoda ku Tokyo 101 0064 Japan...