Preface

This instruction manual describes the proper methods for using the tamping rammer, as well as

simple checks and maintenance.

Be sure to read this instruction manual before using the

rammer

, in order to get full use of the excellent performance of this machine, to improve your

operation and to perform engineering work effectively.

After reading this manual,

store it in a handy location

for easy reference.

For details about the engine in this machine, see the separate instruction manual for the

engine.

For inquiries about repair parts, parts lists, service manuals, and repair of the machine, please

contact the shop where you purchased it, our sales office, or the Mikasa Parts Service Center.

In addition, parts lists are available on the MIKASA website at:

http://www.mikasas.com/english/

Though compact and lightweight, this rammer creates a strong impact and you may expect a

large tamping effect on the ground.

It will compact nearly all types of soil, except soft soil that contains too much moisture.

Use this rammer to tamp the ground for creating roads, embankments, and to prepare the

surface to support buildings. It can also be used when burying gas or water lines, and electric

cables.

Do not use this machine on ground that is harder than the machine can handle, or for driving

pilings or tamping rock beds. Furthermore, use of the machine on sloping ground such as the

side of an embankment, may be make the machine unstable and can cause an accident. It can

also result in premature machine wear due to uneven loads on the machine.

Use the machine with confidence for tamping earth and sand, soil, sand, gravel, and asphalt.

Do not use the machine for other type of jobs.

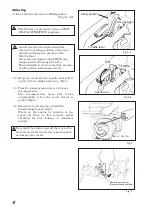

The upper section of the machine functions as a weight and consists of an engine section

guide, a gear reducer section, and reciprocating section. It also accommodates the handle and

the fuel tank sections, which are connected by rubber dampers.

The lower section of the machine which hits the ground, consists of a spring case to engage

sliding motion, a sloping section to allow the machine to tilt toward the front, bellows to cover

the foot, a sliding section, and a protective sleeve.

As the engine speed increases, the centrifugal clutch expands and a pinion gear that is a part

of the clutch drum engages a gear in the crank shaft on the main frame. The engine speed is

decreased in order to produce the required force for tamping.

The rotating motion of the main frame crankshaft is converted to a reciprocating motion through

a connecting rod. This reciprocating motion causes the foot to go up and down through a strong

coil spring. The weight of the main body and the strong force from the engine compress the

spring and the foot moves up and down, striking the ground forcefully.

The illustrations and Figures in this manual may be different from the machine you

actually purchased due to design changes and other reasons for improvement.

Application

Warning about incorrect applications and techniques

Structure

Power transmission

1

Power is provided by an air-cooled, 4-cycle, single-cylinder diesel engine. The output end of the

engine crankshaft is equipped with a centrifugal clutch.

Summary of Contents for MT-76D

Page 2: ......

Page 18: ...Note...

Page 19: ......

Page 20: ...PRINTED IN JAPAN MIKASA SANGYO CO LTD 1 4 3 Sarugakucho Chiyoda ku Tokyo 101 0064 Japan...