Precautions when adding fuel

DANGER

!

When adding fuel.

Adding fuel until it comes too close to the top of the inlet may cause the fuel to overflow.

That is dangerous. Follow the instructions in the engine manual about the specified fuel

level.

When through adding fuel, tighten the tank cap securely.

If you use the machine for a long time, be careful to watch for signs of vibration syndrome.

Since this machine vibrates, operation for a long time may have a negative effect on your

body. Take sufficient breaks while working.

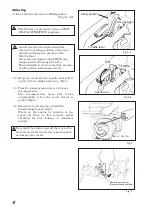

Before starting to operate the machine, check for other people or obstacles that are too

close for safe operation.

When starting the engine, the rammer may jump suddenly. Hold the handle firmly with one

hand and pull the recoil starter with the other hand.

Always be careful around scaffolding. Operate the rammer in a stable manner so that it will

not become unbalanced.

During operation, don't let the foot of the machine come too close to your foot. The plate

may smash your foot.

If you encounter any problems or abnormality with the machine during operation, while

moving it, or stopping operation, stop work immediately.

Before leaving the machine, be sure to turn the engine off. Also, make sure to turn the

engine off if you want to move the machine. When the throttle lever is in the stop position,

the fuel cock is closed. Do not move the lever away from the stop position.

When lifting the machine by the handle, be careful not to pinch your fingers between the

handle and main body.

Do not allow any open flames nearby

while adding fuel. (In particular,

smoking while adding fuel is strictly

prohibited.)

■

■

■

■

■

■

■

■

■

■

■

■

■

■

Be sure to work in a well ventilated location.

Be sure to turn the engine off and wait until it has cooled down.

-

-

-

-

Precautions about where to use the machine

DANGER

!

D O N O T

r u n t h e e n g i n e i n a n

unventilated location, such as indoors

or in a tunnel. The exhaust gas from

the engine is carbon monoxide and is

deadly.

DO NOT

operate the machine near

open fires.

The main parts of the engine, the

muffler, and muffler cover will be very

hot during operation. Be careful not to

touch them during operation or soon

after operation.

Precautions before starting work

CAUTION

!

3

Take the machine to a clear flat location without any combustibles nearby. Be careful not

any fuel. If you do spill some fuel of diesel, wipe it all up.

Summary of Contents for MT-76D

Page 2: ......

Page 18: ...Note...

Page 19: ......

Page 20: ...PRINTED IN JAPAN MIKASA SANGYO CO LTD 1 4 3 Sarugakucho Chiyoda ku Tokyo 101 0064 Japan...