11

7

.

INSPECTION BEFORE OPERATION

Check the machine while the engine is stopped. You may be caught in a rotating

part and be seriously injured.

Check the machine after it has cooled down. Since the muffler is very hot, you may

be burned.

Fig.2

WARNING

!

●

●

Inspection items

Flaws, deformity, dirt

Dirt, flaws, deformity

Loose or missing

Flaws, deformity, cracks, breaks

Flaws, deformity, cracks, breaks

Leaks,oil level,dirt

Leaks,oil level,dirt

Leaks, fuel level, dirt

Leaks, wear, loose parts

Inspection points

Appearance

Air cleaner

Bolts, nuts

Handle

Rubber damper

Engine oil

Main body oil

Fuel tank

Fuel system

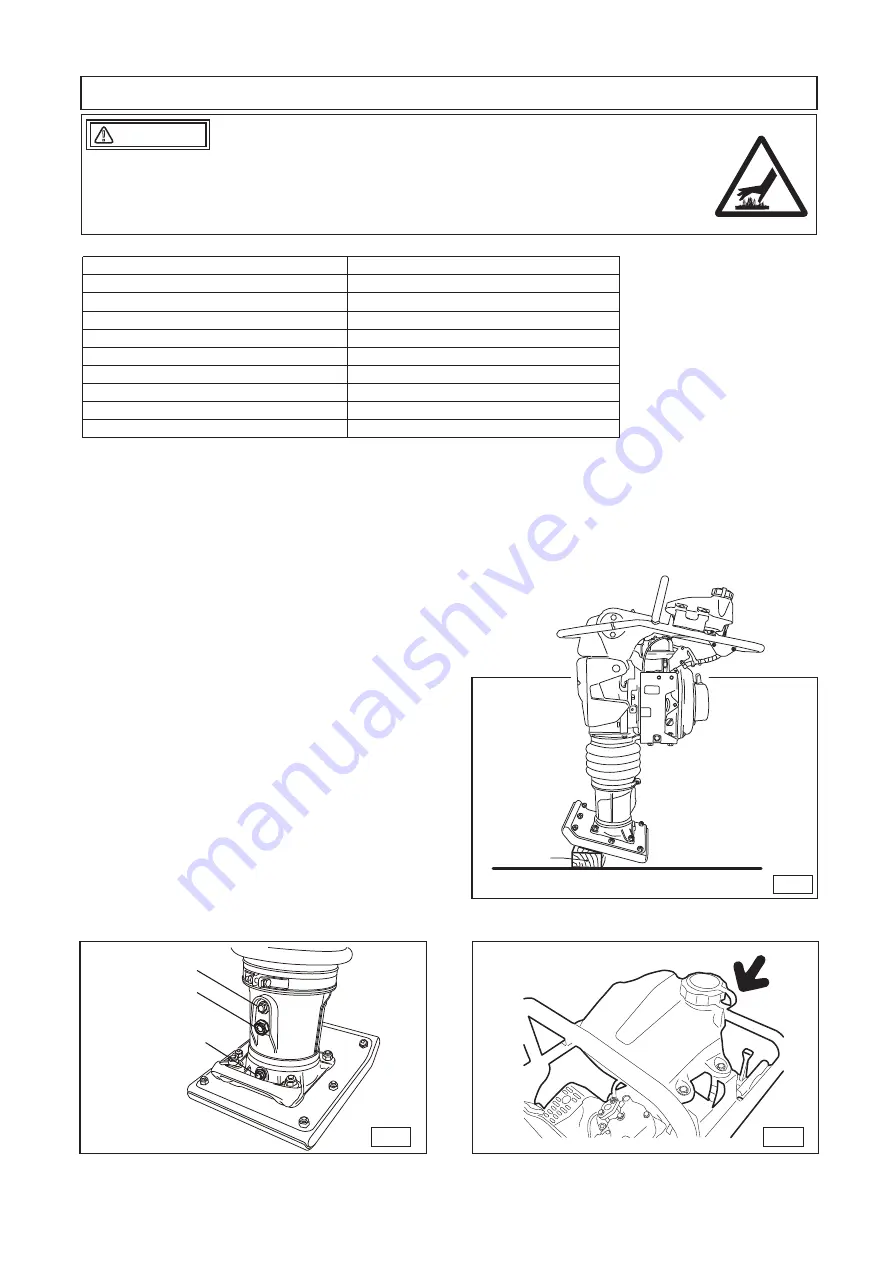

Fig.1

Oil inlet plug

(Check the oil level!!)

Blocking

(Move the engine at vertical position!)

It is extremely important that this section be

read carefully before attempting to operate the

rammer.

Do not use your rammer until this section is

thoroughly understood.

Clean each parts of the machine so that there is no

mud or dirt on them.

Make sure that all bolts and nuts are not loos-

ened. If they are loosened, retighten them to

prevent an accident and trouble.

Replace any missing or damaged safety and operation

decals.

Check the main body oil through the oil gauge on the

protection sleeve on level ground. (Fig.1)

Check the engine oil. For checking the engine

oil level, move the engine to vertical position

and check that the oil is filled at the oil inlet

(800cc). (Fig.2)

Fill the fuel tank with automobile diesel fuel. (Fig.3)

1.

2.

3.

4.

5.

6.

Oil gauge

Oil inlet plug

Fuel tank ( Diesel )

Fig.3

Drain plug