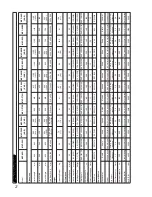

5) model

MVC-40G

MVC-50G

MVC-F60R

(VAS)

MVC-F60H

(VAS)

MVC-F70R

MVC-F70H

6) Equipment

item number

52062 52064

52065 52068

52069 52070

52043 52044

52045

52184 52192

52198 52203

52221 52222

52191 52196

52218 52219

52529 52533

52538 52540

52543 52544

52530 52531

52532 52534

52546

7) power sorce

cont. output

Robin EH09-2D

1.4kW

Robin EH12-2D

2.1kW

Robin EX13

3.2kW

Honda GX120

2.9kW

Robin EX17

4.2kW

Honda GX160

4.0kW

8) Measured

sound power

level(dB)

97

99

100

101

102

102

9) Guaranteed

sound power

level(dB)

105

105

105

105

105

105

10) Max. Sound

pressure

level(dB)

87

90

89

89

91

91

5) model

MVC-F70H

MVC-F80R

(VAS)

MVC-F80H

(VAS)

MVC-88GE

(VAS)

MVC-88GH

(VAS)

MVC-98D

(VAS)

6) Equipment

item number

52530 52531

52532 52534

52546

52567 52568

52569

52564 52565

52363 52383

52390

52367 52370

52371 52373

52374 52391

52395 52396

52385 52386

52387 52388

52389

7) power sorce

cont. output

Honda GX160

4.0kW

Robin EX17

4.2kW

Honda GX160

4.0kW

Robin EX17

4.2kW

Honda GX160

4.0kW

Yanmar L48A

3.5kW

8) Measured

sound power

level(dB)

102

104

102

102

104

104

9) Guaranteed

sound power

level(dB)

105

105

105

105

105

108

10) Max. Sound

pressure

level(dB)

91

94

94

94

94

96

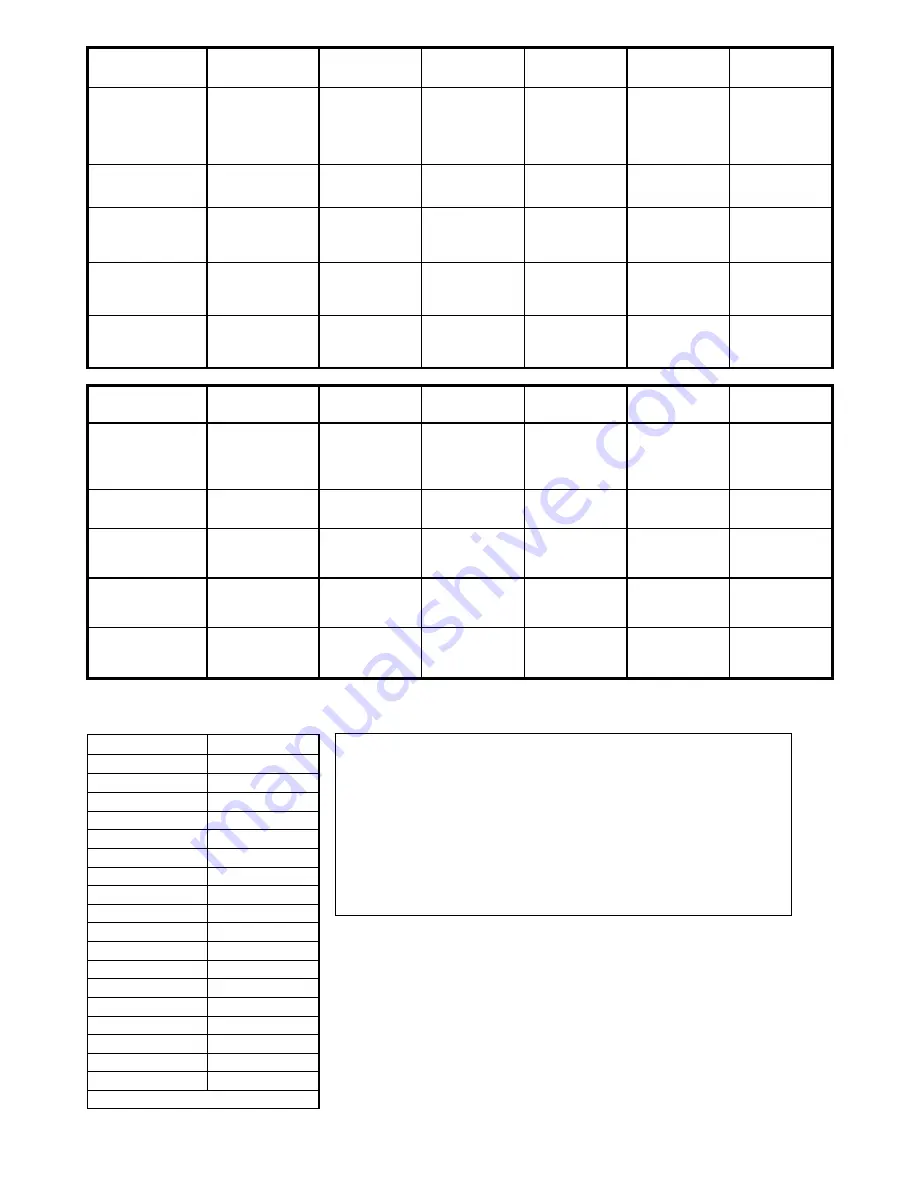

Hand-Arm Vibration Level

Remarks

M

odel

A

h

v

(m/sec

2

)

MVC-40G

5.4

MVC-50G

6.9

MVC-F60H

7.3

MVC-F60R

7.0

MVC-F70H

5.8

MVC-F70R

6.3

MVC-F80H

6.7

MVC-F80R

7.0

MVC-88GH

4.7

MVC-88GE

4.8

MVC-98D

4.4

MVC-F60H VAS

3.3

MVC-F60R VAS

3.2

MVC-F80H VAS

3.8

MVC-F80R VAS

3.5

MVC-88GH VAS

2.1

MVC-88GE VAS

1.7

MVC-98D VAS

2.0

Vibration Level is in comply with EU Directive2002/44/EC

and the value is shown as 3 axix min. vibration level.

Test course ( Crushed gravel ) is in comply with EN500-4.

The above values are subject to change in case that the

machine is modified or/and the required regulations change.