1.Priorto operation

1-1.Make

sure that all dirt,mud,etc.,are

thoroughly removed from the unit prior to

operation. Special effort should be given to the

buttom face of the vibrating

plate and those

areas adjacent to the cooling air inlet of engine,

carburetor, and air cleaner.

1-2 Check all bolts and screws for tightness and

make sure all bolts and screws are securely

tightened. Loose bolts and screws may cause

damage to the unit.

1-3 Check the V-be1t for tightness. The nomal slack

should be approximately 10-15mm(1/2")when

the belts are forcib1y depressed in the midd1e

position between the two sheaves.

If there is excess belt p1ay, there cou1d be a

decrease in the impact force or erratic

vibration, causing machine damage.

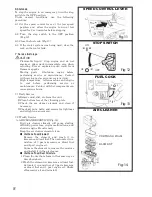

1-4 Check the engine oil level and if the engine oil

level is 1ow,it shou1d be refil1ed. Use the

proper motor oil as suggested in the table

be1ow.(Fig-1)

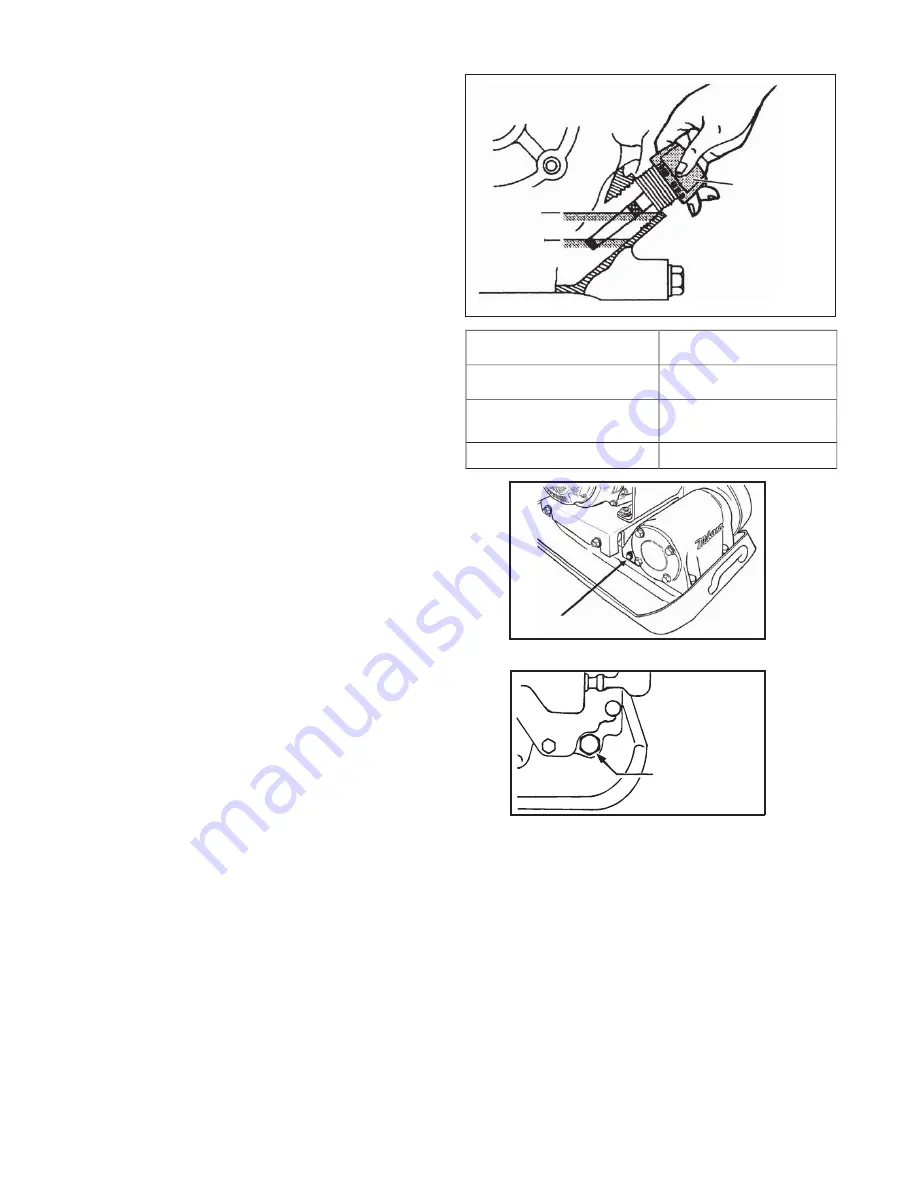

1-5 Remove the oil plug in the vibrator assembly

and check the oil level. Make sure the

compactor is level when checking. The oil level

should be up to the oil plug. Every month or

every 200 hours of operation, replace the oil.

(Fig - 2)

IMPORTANT:

Use the Motor oil SAE

When changing the oil,the old oil can be drained by

tipping the unit.

The oil will drain easily while it is hot.

1-6 A regular grade gasoline should be used in the

engine.

When filling the fuel tank, make sure the fuel

filter is used.

2. Caution

2-l Be careful with the operating place and

ventilation.

Avoid operating the machine in a closed room,

tunnel, or other badly ventilated places, since

its exhaust contains deadly poisonous carbon

monoxide. If the machine is employed

unavoidable operated in such a place,

discharge the exhaust outside the room by a

suitable means.

2-2 Be careful with the hot members.

Mufflers and other hot members are

dangerous. Do not touch them with unprepared

hand.

2-3 Observe with the following cautions when

transporting. Clamp fuel tank cap securely, and

turn the fuel valve OFF at the source during

transportation.

Drain gasoline from fuel tank before

transporting over a long distance or on rough

roads.

2-4 Stop engine without fail before replenishing fuel

tank.

Never replenish gasoline while the engine is

running or remains hot otherwise spilled or

evaporated fuel is liable to catch fire from

engine sparks or muffler heat.

Wipe off spilled fuel , if any, before starting

engine.

Be careful not to spill fuel.

2-5 Keep inflammables away from the vicinity of

the exhaust port.

Be careful with gasoline match, straw and

other inflammables, since the exhaust port is

subjected to a high temperature.

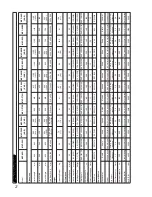

Season or Temperature

Grade of Motor oil

(higher than MS class)

Spring, Sumer or Autumn

+120

°

F to

+

40

°

F

SAE 30

Winter

+40

°

F to

+

15

°

F

SAE 20

Below+15

°F

SAE 10W-30

OIL GAUGE

(OIL FILLER)

LOWER

LEVEL

UPPER

LEVEL

OIL LEVEL PLUG

Fig-2A

MVC-F60,F70

OIL LEVEL PLUG

Fig-2B

MVC-88G

Fig-1

5