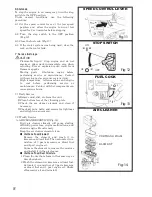

Open by

about

30 degrees

Throttle lever

Fig-5-D

3.Starting

Gasoline Engine

3-l Turn the STOP SWITCH clock-wise to the

position "I"(ON). Fig.3

3-2 Open the fuel cock. Fig.4

3-3 Set the speed control lever l/3 to 1/2 of the way

towards the high speed position Fig.5

3-4 Close the choke lever.

・

If the engine is warm or the ambient

temperature is high, open the choke lever

half-way, or keep it fully open.

・

If the engine is cold or the ambient temperature

is low, close the choke lever fully. Fig.6

3-5

・

Pull the starter handle slowly until resistance

is felt. This is the "compression" point.

Return the handle to its original position and

pull swiftly.

・

Do not pull out the rope all the way.

・

After starting the engine, allow the starter

handle to return to its original position while

still holding the handle. Fig.7

Diesel Engine

3-6 Turn the throttle lever to START position ( open

by about 30 degrees ) ( Fig-5-D )

3-7 Operate Starter

In case of recoil starter

By pulling the starter knob slowly, you will reach

such point where resistance become strong

( compression point ). By pulling it further, you

will find a point where resistance is reduced.

Return the knob but slowly return it original

position. ( Fig.7-D )

CAUTION

Do not pull the rope all the way and do not take

your hand off the pulled knob but slowly return it

original position.

3-8 After starting up the engine, be sure to perform

a warm up run for 2 to 3 minutes. This should

be performed without fail, particularly during

winter season. While doing this, check for

abnormal sound of gas leaking.

Fig-7-D

CHOKE LEVER

Fig- 6

SPEED CONTROL LEVER

Fig- 5

RECOIL STARTER

Fig- 7

FUEL COCK

Fig- 4

CLOSE

OPEN

Fig- 3

STOP SWITCH

“ I ” (ON)

“ O ” (OFF)

6