●

●

●

1.

2.

2-1.

2-2.

2-3.

2-4.

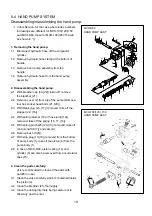

Vibrator case is to be supported by means of Jig B

with its belt side coming to bottom.

Have the key 10x8x19(6) and upper (opposite to belt

side) stop ring(5) engaged to drive shaft.

After piacing such assembly inside the vibrator case,

have the drive gear(7) (with its punched side coming

to top) and stop ring(5) engaged to halfway of the

drive shaft, in such order.

With the Jig A arranged as shown in Fig.15, push the

drive gear into drive shaft by means of press and

engage the lower stop ring(See Fig.16).

Press the bearing of opposite to belt

side(2) into drive shaft(See Fig.17).

Jigs to be used (3 types)

Before proceeding with reassembly, remove liquid

packing thoroughly from mating surface of vibrator

case and compaction plate. Clean and de-grease all

the other parts as well.

Coat the press-fit area with molybdenum grease.

Have both of the two bearings(2) inserted in the belt

side of vibrator case(1) (See Fig.14).

Bearings in use:

MVH-R60: 6206C4

MVH-100(120): 6307C4

MVH-150: NJ307MC4

Within the vibrator case, press the drive gear(7) into

drive shaft(3) with its punched side coming to

top(Opposite to belt side) (See Fig.15).

REASSEMBLY

<Common to MVH-R60, 100 (120) AND 150>

Jig A

Jig B

Jig C

50

6

Φ

70

80

80

10

30

5

Φ

45

55

Re-assembling the driving shaft:

Fig.14

Driven shaft side

Drive shaft side

Belt side

Coat with

molybdenum grease.

Opposite to belt side

Fig.15

Top

Bottom

Jig A

Jig B

Press-in

Punched surface

on opposite

to belt side

Drive side

Coat with

molybdenum grease.

7

6

5

5

3

1

Drive side

Drive side

2

2

5

5

Fig.16

Fig.17

14