6.

7.

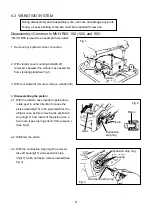

1.

2.

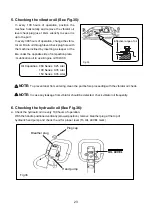

Install bearing holder(8) to driven shaft gear with

four hex socket head bolts 6x30(10). (See Fig.25)

Apply Loctite 271 to the bolts.

Tightening torque: 180kgf-cm

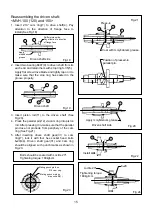

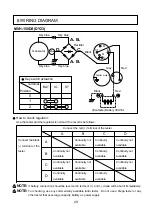

Fit the driven shaft assembly to vibrator case and

after aligning the punch marks of drive gear(30)

and driven gear(31), insert it to bearing(2). (See

Fig.26 and 27.)

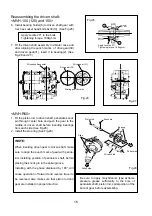

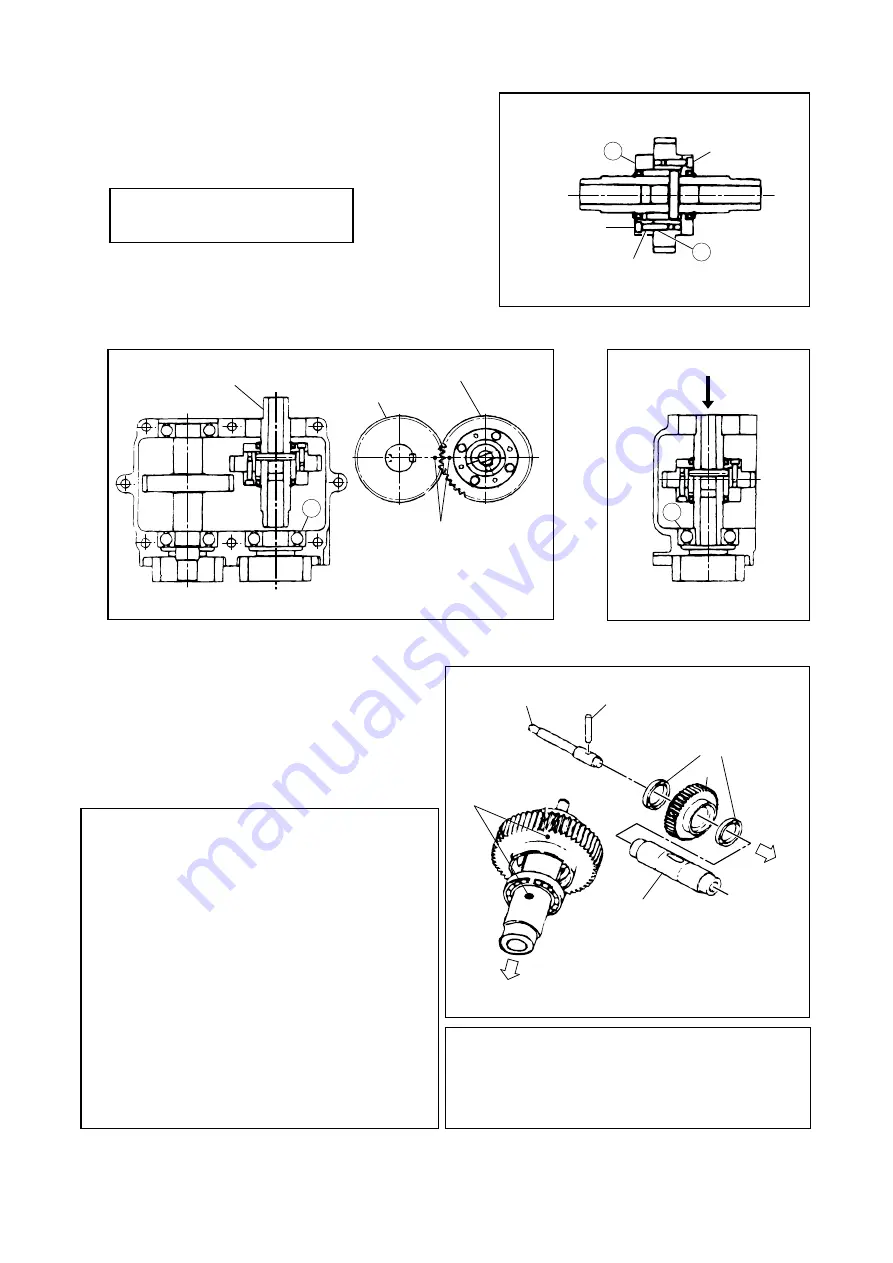

Fit the piston rod to driven shaft, penetrate knock

pin through center hole and push the gear to the

middle of driven shaft before inserting bearings

from each side (See Fig.28).

Install the stop ring (See Fig.28)

!NOTE:

When inserting driven gear to driven shaft, make

sure to align the punch mark of gear with pendu-

lum installing position of pendulum shaft, before

placing the knock pin in the spiral groove.

Installing with the phase displaced by 180

o

, will

cause operation of forward and reverse travel to

be reversed. Aiso make sure that piston rod and

gear are installed in proper direction.

Be sure to apply molybdenum type extreme

pressure grease sufficiently to the bore of

pendulum shaft, piston rod, spiral portion of the

bore of gear, before assembling.

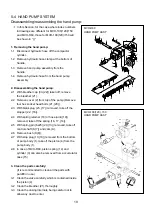

Reassembling the driven shaft:

<MVH-100 (120) and 150>

<MVH-R60>

16

Fig.25

Fig.26

Fig.27

Fig.28

Apply Locktite 271,

Tightening torque: 180kgf-cm

Driven gear (31)

Driven shaft assembl

Drive gear (30)

Mating punch marks

Pulley side

Align

Pulley side

Gear

Knock pin

Piston rod

Bearing

Driven shaft

6

x

20

6

x

30

10

8

2

2