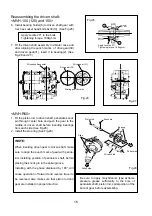

1. Inspection and maintenance chart:

Machine Inspection:

Engine Inspection

(See Engine Instruction Manual for detail)

2. Replacing engine oil:

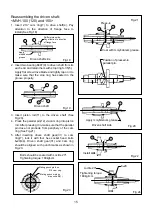

3. Cleaning the air cleaner:

6. PERIODICAL INSPECTION AND MAINTENANCE WORK

21

To enable the use of machine always in its top condition, be sure to conduct maintenance inspection

in accordance with the chart below:

Replace engine oil after first 20 hours and in every 100 hours of operation thereafter. It is easier to

drain oil when engine is warm after its operation (For detail, see engine supplier’s manual).

Air cleaner element should be cleaned, as it becomes dirtier not merely engine starting difficulty, lack

of power or operating deficiency will result in but useful life of the engine itself will be shortened (For

detail, see engine supplier’s manual).

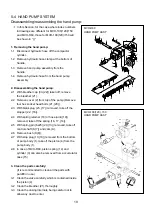

Pre-start up

inspection:

Vibrator oil – Check

Vibrator oil – Replacement

Hydraulic oil – Check

Hydraulic oil – Replacement

V-belt (Clutch) – Inspection

Oil and/or fuel leakage

Tightness of fasteners

Engine oil – Check and replenishment

Engine oil – Replacement

Air cleaner – Clean

Every 8 hours (Daily)

Ditto

Ditto (Replenish to specified level when

insufficient)

At first 20 hours; every 100 hour thereafter

Every 50 hours

Loosened or missing screws

Damage of parts or components

Function of control system components

Leakage in hydraulic system piping

Item

Item

Hours of Operation

Hours of Operation

8 Hours (Daily)

Ditto

Ditto

Ditto

Every 100 hours

Every 300 hours

Every 100 hours

At first 200 hours; every 1,000

hours thereafter

Every 200 hours

Inspection or maintenance service should be conducted on hard and level ground. Be

sure to have engine shutdown before starting such inspection or service work.

Above intervals are for normal operating circumstances. Shorten it or improve the

substance of service according to requirement.

Fuel piping should be replaced in every 2 years

NOTE:

!

NOTE:

!

NOTE:

!