1.

2.

3.

4.

5.

6.

7.

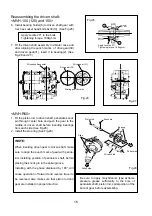

Table of Tightening Torque (kgf-cm)

Table 2

Screw diameter

Material

4T(SS41)

6-8T(S45C)

11T(SCM3)

In case counter

part is made from

aluminum

Hydraulic hose tightening torque: Screw size 1/4 380kgf-cm

4. RULES FOR CONDUCTING SERVICE WORK

3

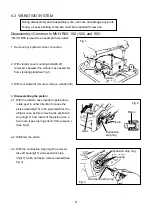

In order to avoid deficient reassembly, know normal status of installation before removing or disasem-

bling any part. Level check or replacement of vibrator oil should be carried out on level ground.

Each time disassembly is made involving oil seal, gasket, packing, o-ring, lock washer or the like,be

sure to replace them with new ones.

Mating surfaces of vibrator case and compaction plate should be sealed with liquid gasket (Clean and

de-grease the mating surfaces thoroughly).

For tightening bolts and nuts, use the specified standard torque and bonding agent (Loctite or the like).

For such bolts and nuts that are not specified, see Table of Tightening Torque. (Before coating with

Loctite, clean the screw with gasoline or thinner.)

NOTE:

All the screw in use with this machine are right handed.

Disassembly work should be conducted where it is free from dust.

Where bonding agent such as Loctite has been in use and screw is hard to loosen, heat it with torch

lamp or the like. Such heated bolt must be replaced with new one, which is of high-tension type as

specified.

Use proper tool in proper manner.

6mm

300~350

8mm

150

250

400

650~700

10mm

300

500

800

12mm

500

800

1,200

16mm

1,100

2,000

2,900

14mm

750

1,300

2,000

18mm

1,400

2,700

4,200

20mm

2,000

3,800

5,600

70

100

100

150

※

For indication in SI Unit (International Unit System), use the conversion of 1kgf-cm=9.80665N-cm