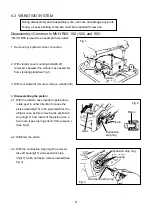

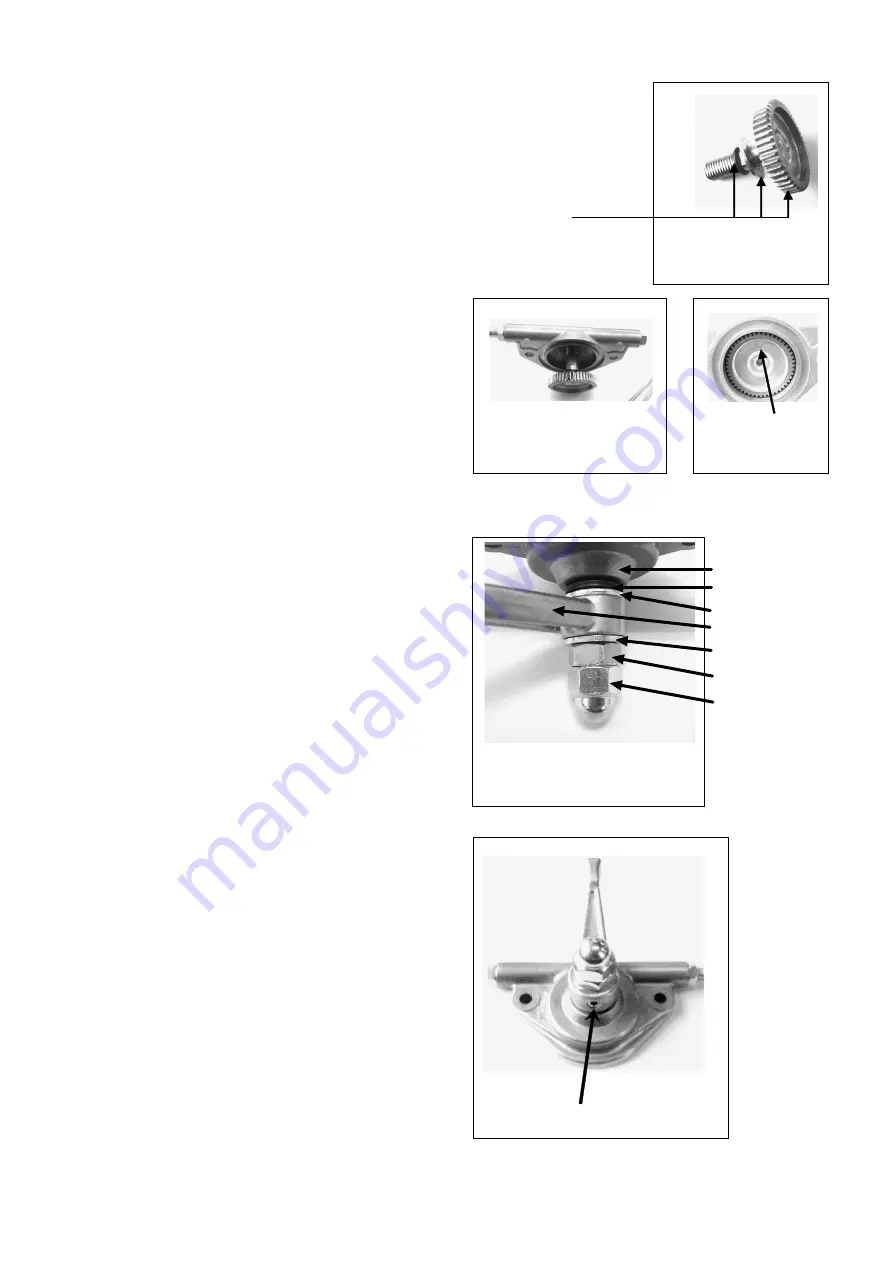

Tooth face of throttle gear,

plain washer and o-ring should

be coated with grease.

Throttle body (51)

Belleville spring (58) x 2

Plain washer M10 (57)

Throttle lever (54)

Plain washer M10 (57)

Nut M10 (61)

Cap nut M10 (60)

Photo I :

Throttle gear, etc.

6

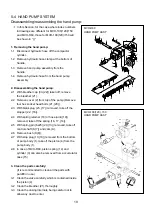

5.

6.

7.

*

Assemble plain washer (57) and o-ring (56) to throttle gear (Photo I).

Assemble throttle gear(52) to throttle body(51) as

follows:

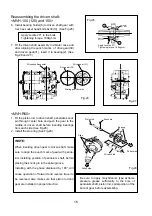

Assemble throttle lever(54) to throttle body(51) (Photo L and M)

Turn-in the hollow setscrew(59) to lock the throttle

lever to throttle gear.

a.

b.

*

*

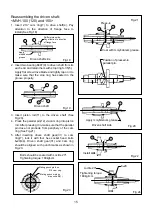

Push-in the governor wire(inner) and shift the

slider(53) all the way to the back (Photo J).

Install with triangle mark of the throttle gear coming

on top (Photo K).

Plain washers should be installed facing each other.

Tightness of throttle lever should be adjusted with

nut M10 and cap nut M10.

To increase resistance in the movement of throttle

lever, add a plain washer M10 on the back end.

Tightening torque: 120kgf-cm

After assembling, throttle lever stops when it reaches top

position as shown in Photo M.

This is the position for the maximum engine rpm.

Photo K :

Triangle mark

Photo J :

Pull the inner part.

Photo L :

Assembling the lever

Photo M :

Hollow setscrew