7

35

38

26

27

25

37

36

33

34

32

28

13

12

19

16

15

14 13

18

17

30

1

15

11

2

7

3 4

21

20

8

4 3

7

5

9

10

24 23

22

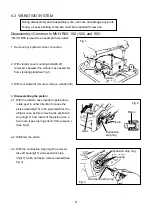

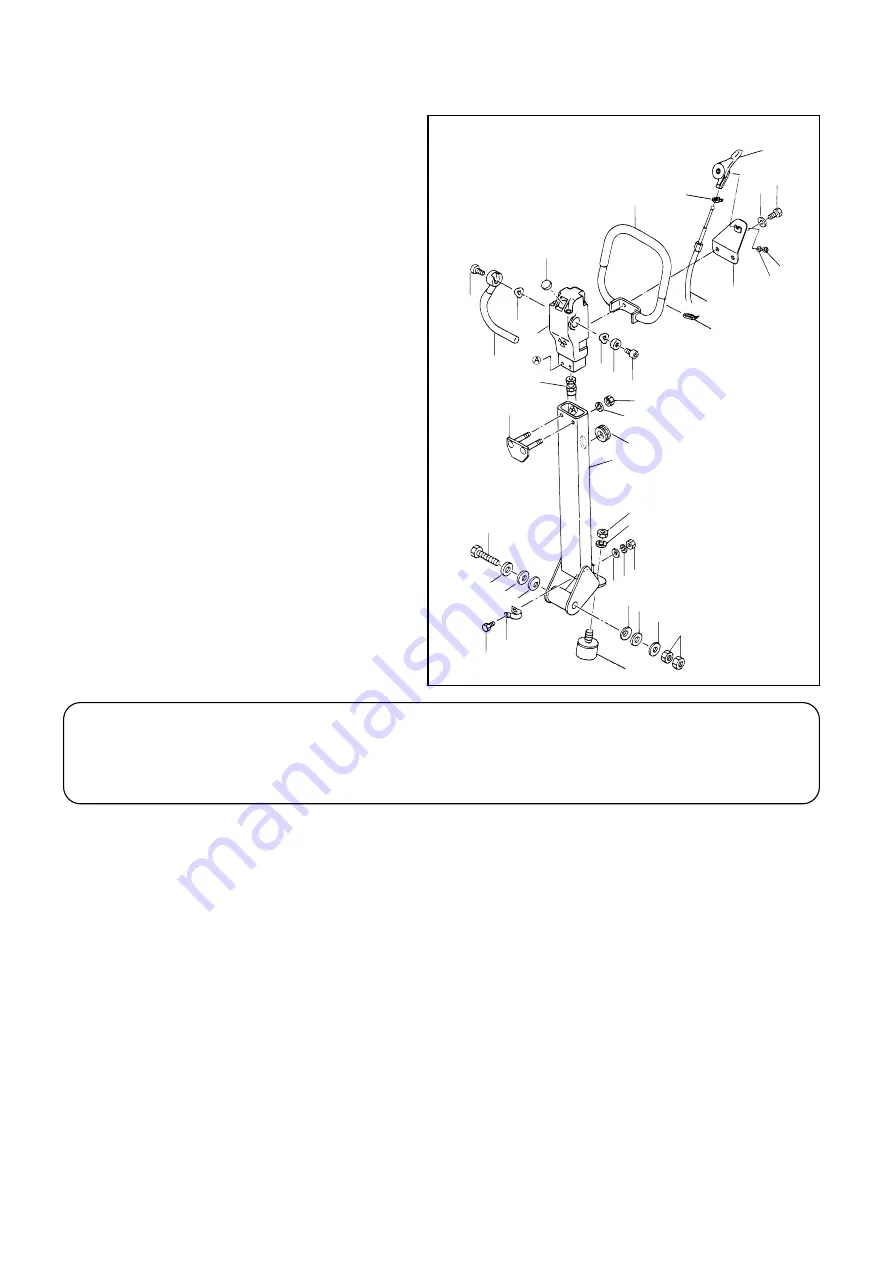

Disassembled operation system

1.

2.

3.

4.

1.

2.

3.

*

Removing two bolts(26) allows to remove the

assembly of grip(25), lever bracket(33) and

throttle lever(35).

Removing double nut(36, 37) causes throttle

lever(35) to come off the lever bracket(33).

To remove throttle lever from machine, remove

governor wire which has been crewed down to

engine.

Removing the bolt(13) allow to remove travel

lever(12) from hand pump(11).

Remove hydraulic hose(19) from the

connector(34) of vibrator shown in the drawing

of disassembled vibrator.

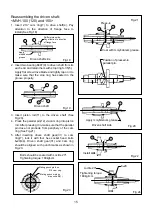

With the two handle root mounting double nuts (5) removed, taking off the bolt(2) allows to remove the

handle(1) from the base.

For installing the handle assembly(1) to the base,first lightly tighten the nut and bolt which have been

tightening the guard hook side of the machine and adjust the resistance of handle movement by means of

double nut(5) before retightening.

Resistance of handle movement should be adjusted with double nut(36,37)

Set rpm of the engine on the high speed end should be adjusted on the engine side by means of engine

setscrew.

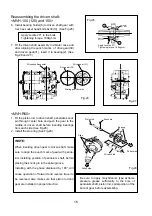

Disassembly and reassembly procedures for MVH-150 is identical to those of MVH-100/120.

Reassembly

Reassembly should be

conducted with the disassembling procedure reversed while observing below:

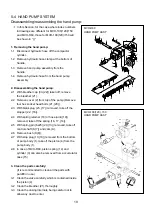

5-1 OPEARTION SYSTEM (MVH-100/120)

Disassembly

After removing hydraulic hose, apply blank cap to prevent any dust from entering.

Removing hose clamp(20), its mounting bolt(21), hand pump locking nut(18) and two stud

bolts (pump)(16) allows to remove the hand pump(11) from handle(1).

! NOTE: