(Refer to previous page)

Keep all hoses away from any areas where heat may be considered too extreme (such as exhaust manifold or turbo). Lines should not to be

allowed to rub on any abrasive or vibrating surfaces. In some applications, 90° fittings on the solenoid valve are necessary to make hose

mounting more flexible. After plumbing has been laid out on vehicle, install O ring fittings supplied to valve. Torque tight. Do not over tighten

any fittings. Install O ring fittings on winch motor. Torque tight. Connect hose number two to port number two on the valve assembly. Attach

the other end of hose number 2 to any port on winch. Connect hose number four to port number four on valve assembly and attach the other

end of number four to the other port on winch. Torque both hoses (both sides) ¼ turn past finger tight.

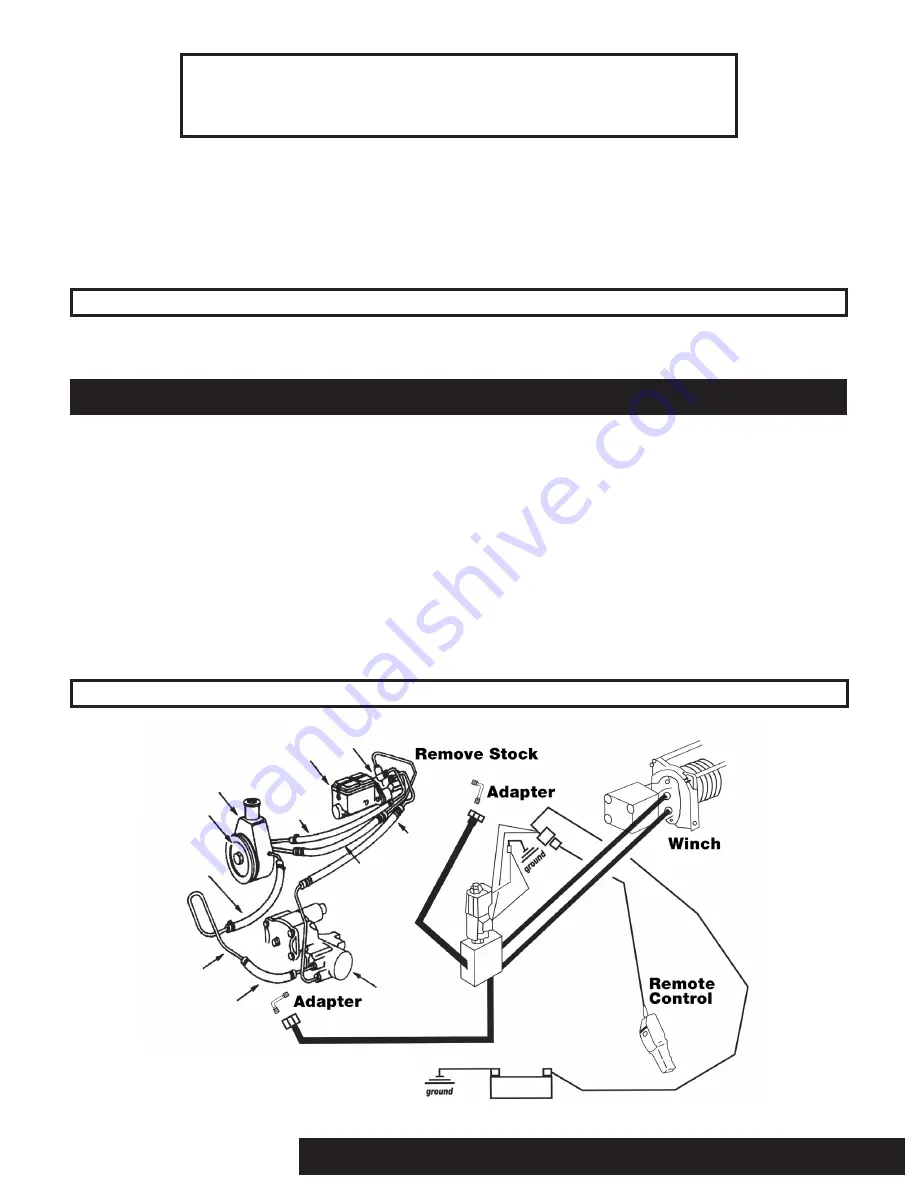

Disconnect original (OEM) high pressure line from the power steering pump to the steering gearbox. If your truck has hydroboost brakes, you

need to remove the high pressure line from the hydroboost to the steering box. NOTE: Low pressure line will normally have a hose clamp (Fig. 3).

NOTE:

Make sure and reuse any 0 rings or seals from OEM tube fittings

NOTE:

If the hand control unit is working backwards, simply reverse the black and white wire connectors on the valve assembly

CAUTION:

Fluid will be lost from the system.

Fig. 3

2121 Blount Road Pompano Beach, FL 33069 MileMarker.com 1.800.886.8647

PAGE 7

PLUMBING CONNECTIONS

Pump

Pump

pulley

Cooler

to pump

return

hose

Cooler

tube

Gear to cooler

return hose

Master cylinder

assembly

Hydroboost

Hydroboost

to pump

return hose

Pump to

hydroboost

pressure

hose

Power steering

gear assembly

Hydroboost

to gear

pressure

hose

(Refer to Fig. 2 on previous page)

Attach any O ring or seal from vehicle’s original tube fitting to tube fitting #3. Connect tube fitting #3 to power steering pump. Torque to

vehicle factory specifications. Connect hose #3 to tube fitting #3. Torque ¼ turn past finger tight. Attach other end of hose #3 to port #3 on

solenoid valve. Torque ¼ turn past finger tight. Attach any O ring or seal from vehicle’s original tube fitting to tube fitting #1. Connect tube

fitting #1 to steering gearbox. Torque to vehicle factory specification. Attach hose #1 to tube fitting #1. Torque ¼ turn past finger tight.

Connect the other end of hose #1 on solenoid valve. Torque ¼ turn past finger tight.

If your application is supplied with an added cooler, remove (OEM) low pressure line from reservoir. Attach hose #5 to existing return line

using male to male coupler and hose clamps supplied. Tighten hose clamps. Connect the other side of hose #5 to cooler supplied with hose

clamp. Tighten hose clamp. Attach hose #6 to cooler and reservoir with hose clamps. Tighten hose clamps. Check fluid level. Replace lost

fluid to system. System will need to be purged. Lift pin on free spool release on winch. Manually pull approximately 10 feet of cable off winch

drum. Lock free spool pin back down. Add fluid until full. Start engine. Power winch cable out five feet. Shut off engine. Check fluid level. Add

fluid until full if necessary. Start engine. Power winch cable into desired position. Turn the vehicle’s front wheels from lock to lock position five

times (all the way to the right and then all the way to the left). This will aid in bleeding out any air that may have gotten into the system.