OWNER’S

INFORMATION

15

Servicing Your Fireplace

We recommend having your fi replace serviced every year. Contact your supplier quoting the model

number. It will be helpful if the appliance’s serial number can also be quoted. These numbers are

on the information card. The replacement parts are shown at the end of this manual. Please always

quote the part number and description when requesting spare parts.

Safe Operation List

To be performed by a qualifi ed technician only

1. Inspect and operate the pressure relief mechanism to verify relief mechanisms are free from

obstruction to operate. See

Cleaning Your Fireplace: To re

fi

t the window

section of this manual.

2. Clean glass window with a suitable fi replace glass cleaner. Abrasive cleaners must not be used.

Be careful not to scratch the glass when cleaning. See

Cleaning Your Fireplace

section of this manual.

3. Inspect the operation of the fl ame safety system Pilot or Flame rectifi cation device.

4. Inspect and ensure the lighting of the main burner occurs within 4 seconds of the main gas valve

opening. Visual inspection should match that outlined in the appliance instruction manual. Inspect

primary air openings for blockage. See

Checking Pilot and Burner Flame

section of this manual.

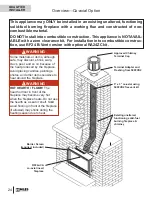

5. Inspect condition of vent and vent terminal for sooting or obstruction and correct if present.

6. Vacuum and clean any debris in the fi rebox that is not supposed to be there.

7. Test and measure the fl ame failure response time of the fl ame safety system.

It must de-energize the safety shutoff in no more than 30 seconds.

8. Check all accessible gas-carrying tubes, connections, pipes and other components for leaks.

See

Set up Gas Supply

section of this manual.

Annual Inspection

In order to maintain the safe operation of your fi replace, contact your dealer to have a qualifi ed

technician go over the list below and make the necessary verifi cations at least once every year.

Servicing & Maintenance