Operator's Manua

l

: Mi

l

lcreek 6700P

&

8700P PTO Spreaders

SECTION 1 : INTRODUCTION

Guide to this Manual

This manual contains all the informationnecessaryto safely operate and maintain the Millcreek 67000P or

8700P PTO Spreader. Consult the Table of Contents for a detailed list of topics covered. You'll find this

manual's step-by-step procedures easy to follow and understand. Should questions arise, please contact your

Millcreek dealer before starting any of the procedures in this manual.

NOTE: Proced

u

res provided in this manual apply to

both spreader models (Model 67000P and

Model 8700P) u

nl

ess specifically noted otherwise.

Regarding the information presented in this manual:

•

All safety, operating, and servicing information reflects current production models at the time

of publication of this manual.

•

References made to left, right, front, and rear are those directions viewed when facing the

unit from the rear.

Please read all sections in the manual carefully--including the important safety information found in

this section--before beginning any assembly/operation procedures; doing so allows you to use your

Millcreek Spreader safely with optimal performance.

For Your Safety ...

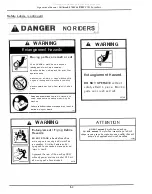

For your safety, Millcreek documentation contains the following types of safety statements (listed here

in order of increasing intensity):

•

NOTE:

A clarification of previous information or additional pertinent information.

•

ATTENTION:

A safety statement indicating that potential equipment damage may occur if

instructions are not followed.

A

CAUTION:

A safety statement that reminds of safety practices or directs attention to unsafe

practices which could result in personal injury if proper precautions are not taken.

A

WARNING:

A

strong

safety statement indicating that a hazard exists which can result in

injury or death if proper precautions are not taken.

A

DANGER!

The utmost levels of safety must be observed;

an extreme hazard exists which

would result in high probability of death or irreparable serious personal injury if proper

precautions are not taken.

The best operator is a careful operator.

By using common sense, observing general safety rules, and

adhering to the precautions specific to the spreader, you, the operator, can promote safe equipment

operation.

1-1

All manuals and user guides at all-guides.com