OM-2243 Page 17

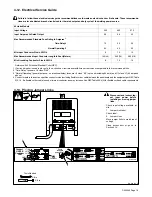

4-8. Weld Output Terminals And Selecting Cable Sizes

!

Turn Off power before

Total Cable (Copper) Length In Weld Circuit Not Exceeding

!

Turn Off power before

connecting to weld

output terminals.

100 ft (30 m) Or Less

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

Welding

Amperes

10

−

60%

Duty

Cycle

60

−

100%

Duty Cycle

10

−

100% Duty Cycle

100

4

4

4

3

2

1

1/0

1/0

150

3

3

2

1

1/0

2/0

3/0

3/0

200

3

2

1

1/0

2/0

3/0

4/0

4/0

250

2

1

1/0

2/0

3/0

4/0

2-2/0

2-2/0

300

1

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

350

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

Negative

Positive

Terminal

400

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-4/0

2-4/0

Terminal

500

2/0

3/0

4/0

2-2/0

2-3/0

2-4/0

3-3/0

3-3/0

600

3/0

4/0

2-2/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

700

4/0

2-2/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

4-4/0

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. Contact your distributor for

the mm

2

equivalent weld cable sizes.

S-0007-E

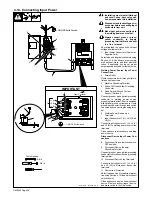

4-9. Connecting Weld Output Cables

803 778-B

!

Turn off power before connecting to

weld output terminals.

!

Failure to properly connect weld

cables may cause excessive heat

and start a fire, or damage your ma-

chine.

1

Weld Output Terminal

2

Supplied Weld Output Terminal Nut

3

Weld Cable Terminal

4

Copper Bar

Remove supplied nut from weld output ter-

minal. Slide weld cable terminal onto weld

output terminal and secure with nut so that

weld cable terminal is tight against copper

bar.

Do not place anything between weld

cable terminal and copper bar. Make

sure that the surfaces of the weld cable

terminal and copper bar are clean.

Tools Needed:

3/4 in (19 mm)

4

2

3

Do not place

anything between

Correct Installation

Incorrect Installation

1

weld cable terminal

and copper bar.

Summary of Contents for NT 456 CC

Page 4: ...Notes ...

Page 14: ...OM 2243 Page 10 ...