OM-6611 Page 12

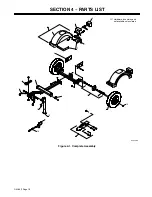

3-8. Tightening Trailer Hardware

Final-tighten trailer hardware installed in

earlier steps to torque values shown.

Tools Needed:

1/2, 9/16, 3/4, 15/16 in

802 817 / 802 818

9/16, 3/4, 15/16 in

Tighten to

75 ft lb

(102 N

.

m).

Tighten

to 30 ft lb

(41 N

.

m).

Tighten lug

nuts to 70 ft

lb

(95 N

.

m).

Tighten to 75 ft

lb

(101 N

.

m).

Tighten to

150 ft lb

(203 N

.

m).

Tighten to

150 ft lb

(203 N

.

m).

Tighten to 30

ft lb

(41 N

.

m).

Summary of Contents for RCT-224 Trailer

Page 19: ...OM 6611 Page 17 Notes ...

Page 22: ......