While Job 100 runs the second time in Automatic mode

and manipulator performs welding operations for Pro-

grams 100 and 200, finished parts for Programs 300,

400, and 500 from first run of Job 100 are unloaded

and new parts are loaded in side 000 fixtures.

Each additional run of Job 100 rotates mounting plate

and runs weld programs that match parts located at

weld side of turntable while finished parts are unloaded

and

new

parts

loaded

in

fixtures

at

parts

loading/unloading side.

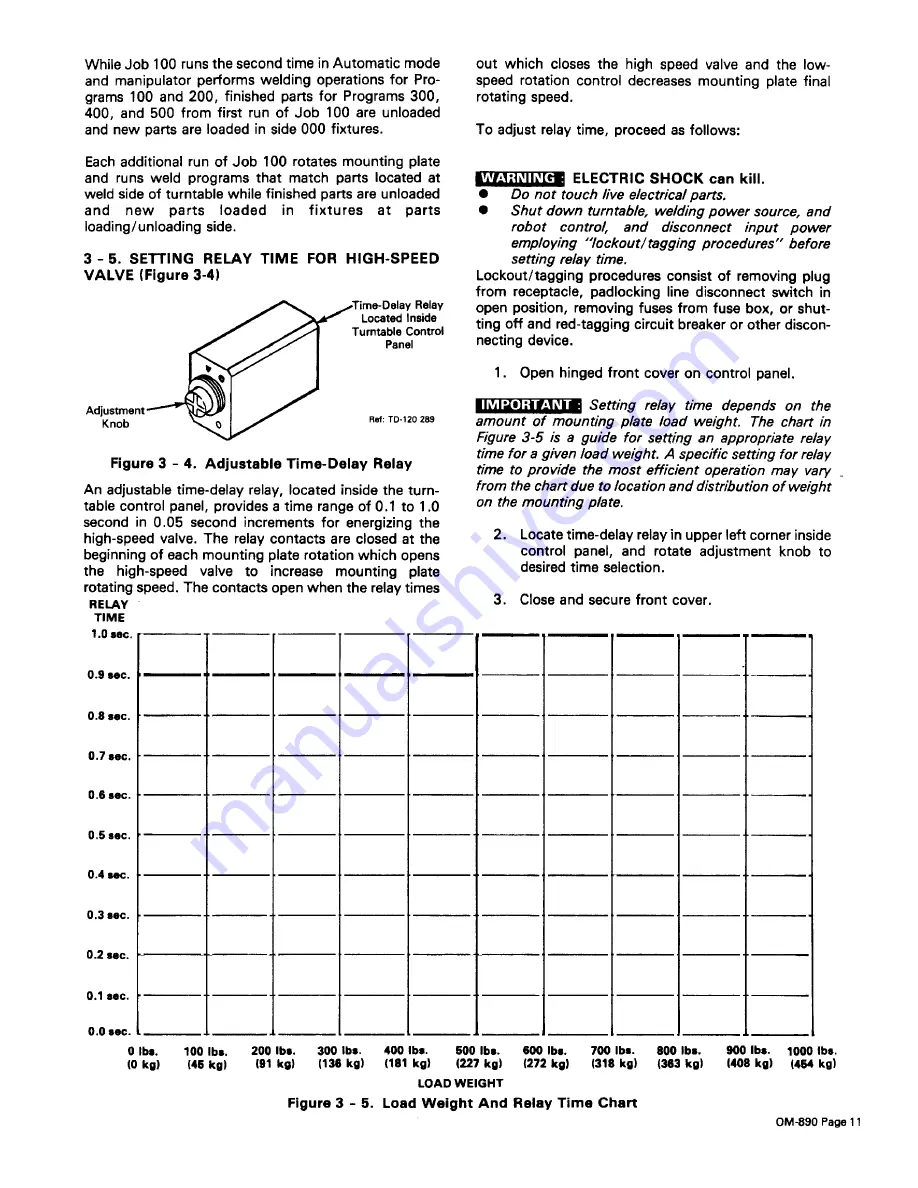

3

-

5. SETTING RELAY TIME FOR

VALVE (Figure 3-4)

HIGH-SPEED

Figure 3

-

4. Adjustable Time-Delay Relay

An adjustable time-delay relay, located inside the turn-

table control panel, provides a time range of 0.1 to 1 .0

second in 0.05 second increments for energizing the

high-speed valve. The relay contacts are closed at the

beginning of each mounting plate rotation which opens

the high-speed valve to increase mounting plate

rotating speed. The contacts open when the relay times

RELAY

TIME

1.0 sec.

out which closes the high speed valve and the low-

speed rotation control decreases mounting plate final

rotating speed.

To adjust relay time, proceed as follows:

WARNING:

ELECTRIC SHOCK can kill.

•

Do not touch live electrical parts.

•

Shut down turntable, welding power source, and

robot control,

and disconnect input power

employing “lockout/tagging procedures” before

setting relay time.

Lockout/tagging procedures consist of removing plug

from receptacle, padlocking line disconnect switch in

open position, removing fuses from fuse box, or shut-

ting off and red-tagging circuit breaker or other discon-

necting device.

1. Open hinged front cover on control panel.

IMPORTANT:

Setting relay time depends on the

Ret TD-120 289

amount of mounting plate load weight. The chart in

Figure 3-5 is a guide for setting an appropriate relay

time for a given load weight. A specific setting for relay

time to provide the most efficient operation may vary

from the chart due to location and distribution ofweight

on the mounting plate.

2. Locate time-delay relay in upper left corner inside

control panel, and rotate adjustment knob to

desired time selection.

3. Close and secure front cover.

——

0 lbs.

100 lbs.

200 lbs.

300 lbs.

400 lbs.

500 Ibm.

600 lbs.

700 lbs.

800 ibm.

(0 kg)

(45 kg)

(91 kg)

1136 kg)

(¶81 kg)

(227 kg)

(272 kg)

(318 kg)

(363 kg)

900 lbs.

1000 lbs.

(408 kg)

(454 kg)

Figure 3

-

5.

LOAD WEIGHT

Load Weight And Relay

Time

Chart

Turntable control

Panel

0.9 sec.

0.8 sec.

0.7 sec.

0.6

sec.

0.5 sec.

0.4 sec.

0.3 sec.

0.2 sec.

0.1 sec.

0.0 sec.

OM-83O Page 11