2

Pre-Delivery Check List

After the Miller Trailer Sprayer has been completely set-up,

the following inspections MUST be made before delivering

it to the customer. Check off each item after prescribed

action is taken.

NO parts on the unit have been damaged in shipment.

Check for such things as dents and loose or missing

parts; correct or replace components as required.

Verify correct nozzle spacing.

Adjust axles per customer's wheel spacing

request.

If applicable, sprayer has the correct hydraulically

driven centrifugal pump for the customer's tractor

hydraulics.

Inflate tires to recommended pressure as described

in the Maintenance Section of the Operator Manual.

Tighten wheel nuts to correct torque (150 ft lb).

Make sure all bolts and other fasteners are

tightened or adjusted properly.

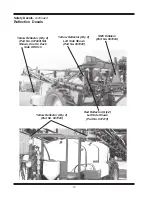

As applicable, the Cylinders, Hoses and Fittings are

NOT damaged, leaking or loosely connected.

Rotating PTO Shields turn freely.

Lubricate grease fittings.

Safety decals are in place and legible.

Hook the sprayer to the appropriate RPM tractor and

test run it while checking that proper operation is

exhibited by all components.

Check that:

Partially fill tank with water, and operate sprayer to

inspect fittings and hose connections for leaks.

With water in tank, be sure tank bands are tight.

All accessories function correctly.

Transport lights operate properly.

Hoses secured and not in contact with any moving

parts.

Hydraulic systems operate properly.

Delivery Check List

The following check list is an important reminder of

valuable information that MUST be passed on to the

customer at the time the unit is delivered. Check off

each item as you explain it to the customer.

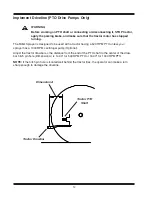

Sprayers with power take off (PTO) driven pumps

must have the tractor drawbar adjusted per instruc-

tions on page 12.

Make sure customers know how to connect hydraulic

pumps on sprayers that are equipped for tractor

hydraulics.

Install electric control box per instructions in separate

control box manual.

Give the customer this operator’s manual. Instruct

them to be sure to read and completely understand its

contents before attempting to operate the unit.

Give the customer the Agricultural Implement Driv-

eline safety manual (907228). Instruct the customer

to be sure to read and completely understand its

contents before attempting to operate the unit.

Explain the warranty.

Explain that regular lubrication and proper adjust-

ments are required for continued proper operation

and long life. Review the maintenance section of this

manual with the customer.

Complete the dealer and warranty registration card.

Have the customer sign it and return it to Miller-St.

Nazianz.

Included with this manual are separate operator/

installation manuals for some components. Be sure

to read and completely understand the contents of

these before operating the sprayer.

I acknowledge that the above points were reviewed with

me at the time of delivery.

_____________________________________________

Dealership's Name

_____________________________________________

Dealer Representative’s Name

_____________________________________________

Date Checklist Filled Out

_____________________________________________

Model Number.

Serial Number.

_____________________________________________

Customer's Signature

_____________________________________________

Date Delivered

(Customer Copy)

Trailer Sprayer

Summary of Contents for 500 BW

Page 6: ......

Page 31: ...27 Spray Tip Wear...

Page 38: ...34 TeeJet Air Induction Spray Tips At Various Speeds And Pressures 20 Inch Tip Spacing...

Page 94: ......

Page 96: ...2007 by Miller St Nazianz Inc...