Summary of Contents for Axcess E 300

Page 14: ...OM 244 814 Page 10 ...

Page 18: ...OM 244 814 Page 14 Notes ...

Page 22: ...OM 244 814 Page 18 Notes ...

Page 26: ...OM 244 814 Page 22 Notes ...

Page 30: ...OM 244 814 Page 26 Notes ...

Page 56: ...OM 244 814 Page 52 Notes ...

Page 63: ...Trouble OM 244 814 Page 59 Notes ...

Page 68: ...OM 244 814 Page 64 Figure 14 2 Circuit Diagram For Axcess E 300 2 Of 2 ...

Page 69: ...Circuits OM 244 814 Page 65 248 763 E Part 2 Of 2 ...

Page 70: ...OM 244 814 Page 66 Figure 14 3 Circuit Diagram For Axcess E 450 1 Of 2 ...

Page 71: ...Circuits OM 244 814 Page 67 245 131 F Part 1 Of 2 ...

Page 72: ...OM 244 814 Page 68 Figure 14 4 Circuit Diagram For Axcess E 450 2 Of 2 ...

Page 73: ...Circuits OM 244 814 Page 69 245 131 F Part 2 Of 2 ...

Page 74: ...OM 244 814 Page 70 Figure 14 5 Circuit Diagram For Axcess E 675 1 Of 2 ...

Page 75: ...Circuits OM 244 814 Page 71 250 570 C Part 1 Of 2 ...

Page 76: ...OM 244 814 Page 72 Figure 14 6 Circuit Diagram For Axcess E 675 2 Of 2 ...

Page 77: ...Circuits OM 244 814 Page 73 250 570 C Part 2 Of 2 ...

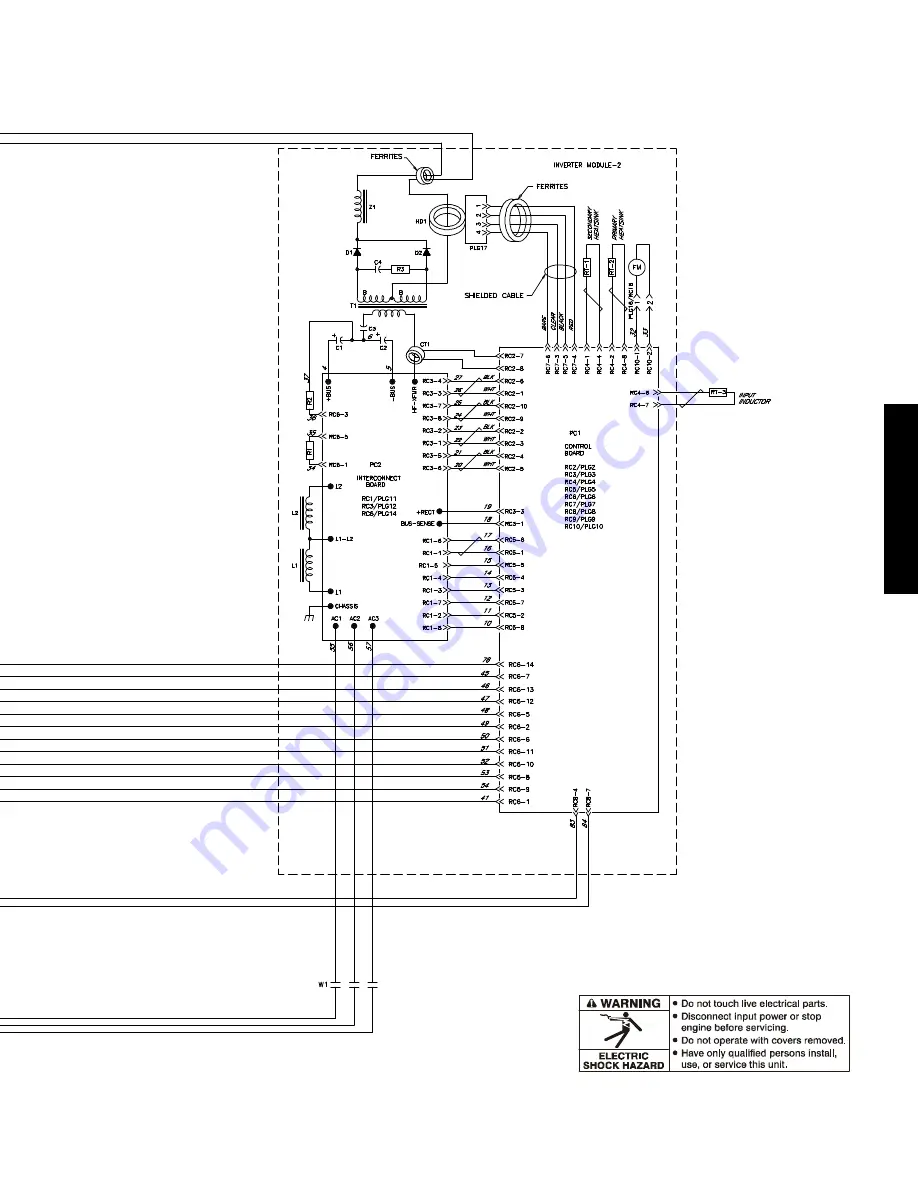

Page 78: ...OM 244 814 Page 74 Figure 14 7 Circuit Diagram For Axcess E Module ...

Page 79: ...Circuits OM 244 814 Page 75 250 571 C ...

Page 80: ...OM 244 814 Page 76 Notes ...

Page 106: ...Notes ...