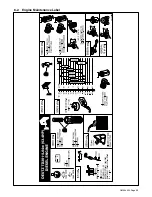

OM-244 023 Page 28

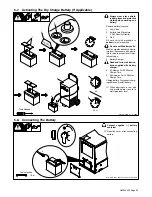

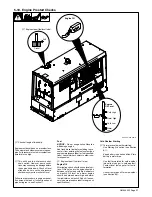

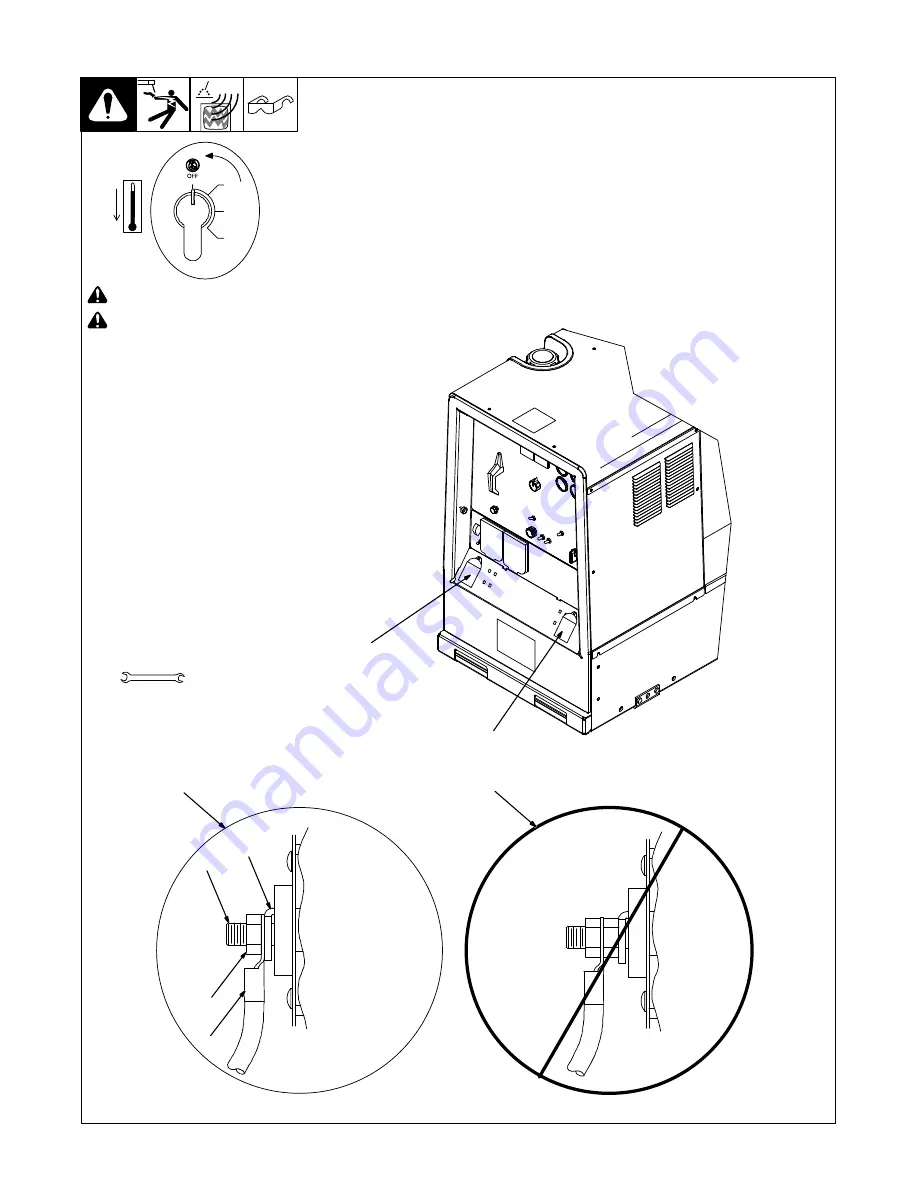

5-11. Connecting To Weld Output Terminals

!

Stop engine.

!

Failure to properly connect weld

cables may cause excessive heat and

start a fire, or damage your machine.

Do not place anything between weld cable

terminal and copper bar. Make sure that

the surface of the weld cable terminal and

copper bar are both clean.

1

Correct Weld Cable Connection

2

Incorrect Weld Cable Connection

3

Weld Output Terminal

4

Supplied Weld Output Terminal Nut

5

Weld Cable Terminal

6

Copper Bar

Remove supplied nut from weld output termi-

nal. Slide weld cable terminal onto weld output

terminal and secure with nut so that weld cable

terminal is tight against copper bar.

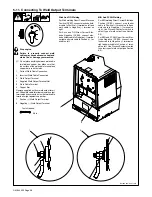

7

Positive (+) Weld Output Terminal

8

Negative (

−

) Weld Output Terminal

Ref 803 452 / 803 778-B

Tools Needed:

3/4 in.

MIG And FCAW Welding

For MIG welding Direct Current Electrode

Positive (DCEP), connect wire feeder

cable to Positive (+) terminal on left and

work cable to Negative (

−

) terminal on

right. Use Process/Contactor switch to

select type of weld output (see Section

6-3).

For MIG and FCAW Direct Current Elec-

trode Negative (DCEN), connect wire

feeder cable to Negative (

−

) terminal on

right and work cable to Positive (+) termi-

nal on left. Use Process/Contactor switch

to select type of weld output (see Section

7

Stick And TIG Welding

For Stick welding Direct Current Electrode

Positive (DCEP), connect electrode hold-

er cable to Positive (+) terminal on left and

work cable to Negative (

−

) terminal on

right.

For Stick and TIG Direct Current Elec-

trode Negative (DCEN), connect elec-

trode holder cable to Negative (

−

) terminal

on right and work cable to Positive (+) ter-

minal on left.

2

1

6

4

5

3

8