OM-244 023 Page 34

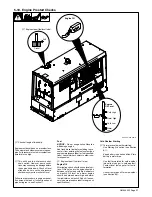

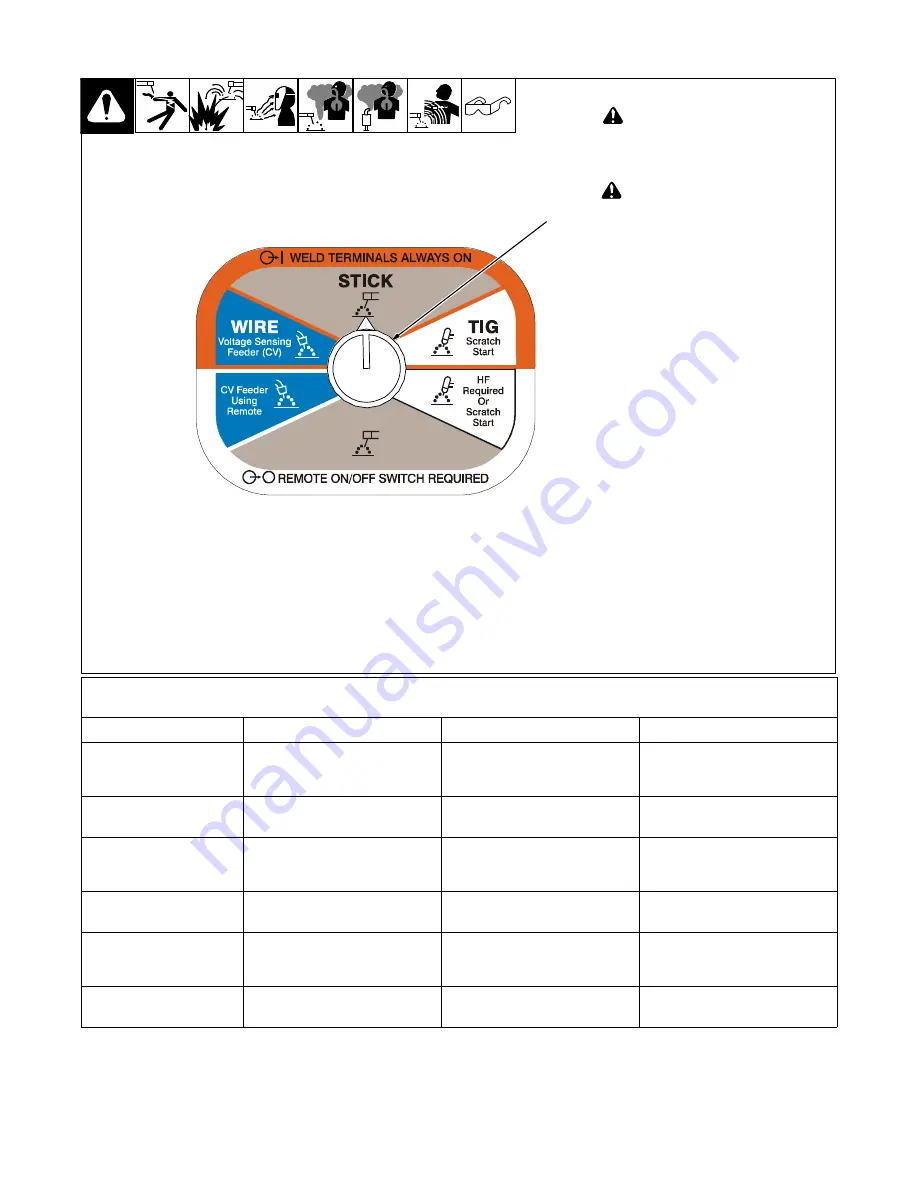

6-3. Process/Contactor Switch

236 975-A

1

1

Process/Contactor Switch

!

Weld output terminals are ener-

gized when Process/Contactor

switch is in a Weld Terminals Al-

ways On position and the en-

gine is running.

!

DC voltage is still present at the

weld terminals when Process/

Contactor switch is in the Re-

mote On/Off Switch Required

−

Stick position and the engine is

running.

Use switch to select weld process and

weld output on/off control (see table be-

low and Section 6-4).

Place switch in Remote On/Off Switch

Required positions to turn weld output

on and off with a device connected to

the remote 14 receptacle.

Place switch in Weld Terminals Always

On positions for weld output to be on

whenever the engine is running.

Use Stick position for air carbon arc

(CAC-A) cutting and gouging.

When switch is in a Stick position, the

arc drive (dig) circuit provides addition-

al amperage during low voltage (short

arc length conditions) to prevent “stick-

ing” electrodes.

The arc drive (dig) circuit is disabled

when switch is in MIG or TIG positions.

The engine auto idle option does

not work in the Remote On/Off

Switch Required-TIG mode.

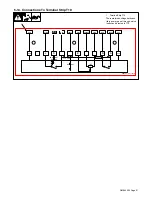

Process/Contactor Switch Settings

Switch Setting

Process

Output On/Off Control

Engine Auto Idle (Optional)

Remote On/Off Switch Re-

quired

−

TIG, HF Required

Or Scratch Start TIG

GTAW With HF Unit, Pulsing

Device, Or Remote Control

At Remote 14 Receptacle

Not Active

Remote On/Off Switch

Required

−

Stick

Stick (SMAW) With Remote On/Off

At Remote 14 Receptacle

Active

Remote On/Off Switch

Required

−

CV Feeder

Using Remote

MIG (GMAW)

At Remote 14 Receptacle

Active

Weld Terminals Always On

−

Wire

MIG (GMAW)

Electrode Hot

Active

Weld Terminals Always On

−

Stick

Stick (SMAW),

Air Carbon Arc (CAC-A) Cutting

And Gouging

Electrode Hot

Active

Weld Terminals Always On

−

TIG, Scratch Start

TIG Scratch Start (GTAW)

Electrode Hot

Active