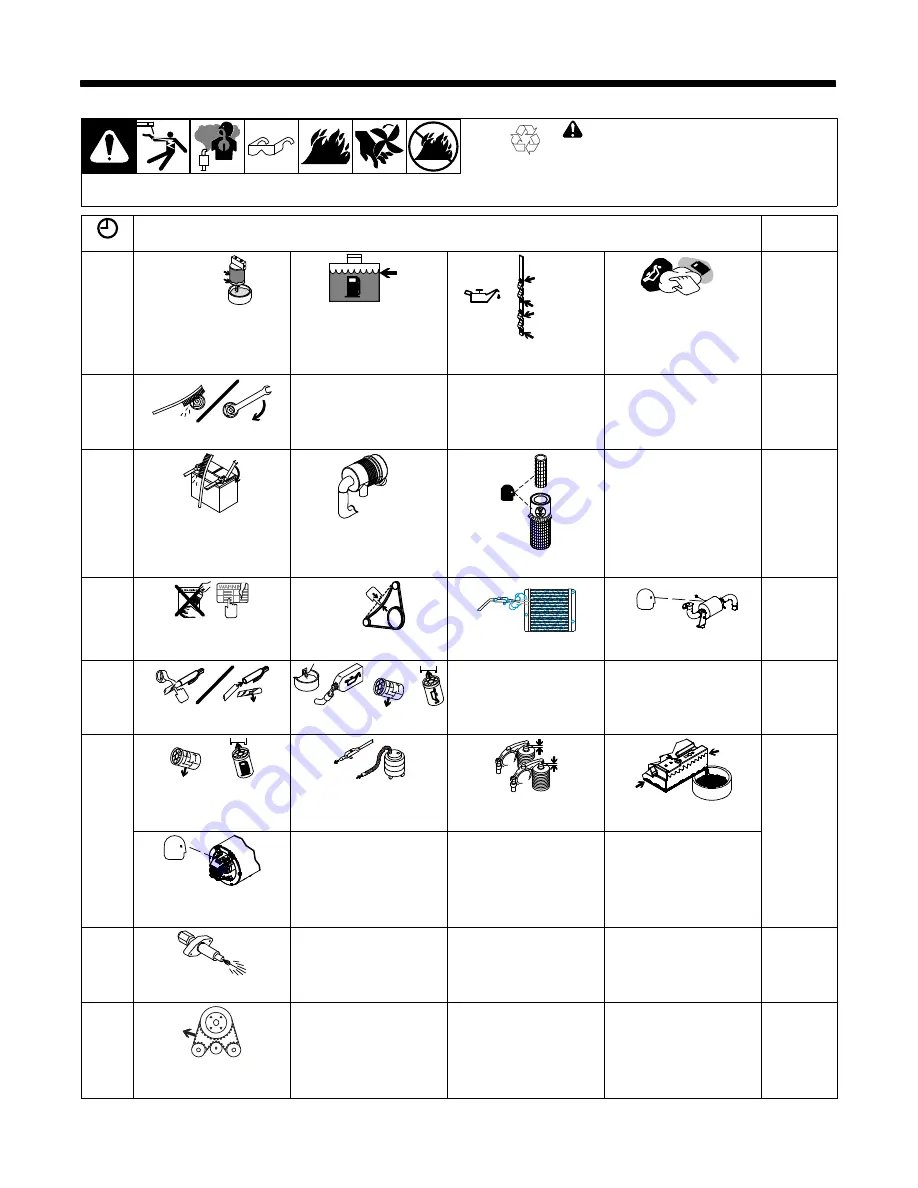

OM-244 023 Page 38

SECTION 8

−

ENGINE/GENERATOR MAINTENANCE

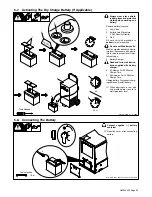

8-1. Routine Maintenance

!

Stop engine before maintaining.

See Engine Manual and Maintenance Label

for important start-up, service, and storage

information. Service engine more often if

used in severe conditions.

Recycle engine

fluids.

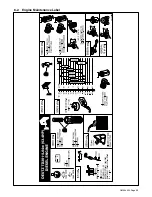

= Check

= Change

= Clean

= Replace

* To be done by Factory Authorized Service Agent

Reference

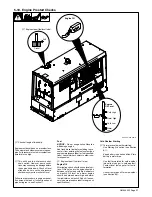

Every

8

Hours

FUEL

WATER

Cold High

Cold Low

Warm High

Warm Low

Section

Fuel/Water Separator

Fuel Level

Oil Level

Oil, Fuel Spills

Every

50

Hours

Weld Terminals

Every

100

Hours

Battery Terminals

Air Cleaner Hoses

Air Cleaner Element

Every

250

Hours

1/2 in.

(13 mm)

Engine

Manual,

Unreadable Labels

Fan Belt Tension

Cooling System

Spark Arrestor

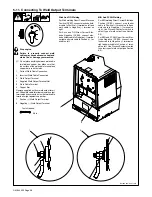

Every

500

Hours

NOTICE

−

Change engine

oil and filter after initial 50 to

75 hours of use.

Weld Cables

Oil

Oil Filter

Every

1000

Hours

OR

SLUDGE

FUEL

8-6 and

Engine

Manual

Fuel Filter

Inside Unit

Valve Clearance*

Drain Sludge

Slip Rings*

Brushes*

Every

3000

Hours

Injectors*

Every

6000

Hours

or 5

Years

Engine Timing Belt