6

5.0 Inspection, Operation

and Maintenance

5.1 Inspection and Operation

WARNING

The ManHandler Hoist/Winch must be

inspected before each use. If the unit is

used as an emergency retrieval device,

it must be inspected prior to personnel

entering the confined space in order to

facilitate a quick recovery. In addition

to the inspection required before each

use, a competent person must inspect

this unit at least annually. This periodic

inspection should be set by the user’s

employer. Annual factory recertification

is not required unless the unit is

subjected to the forces of arresting a fall

or affecting a rescue

CAUTION

Always wear gloves when inspecting

wire rope/cable units; broken strands

can cause injury!

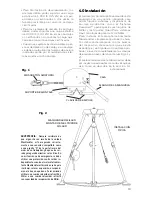

1.

Device Housing and Parts/Mounting

Bracket:

Inspect the unit for bent,

cracked, distorted, worn, malfunctioning

or damaged parts; loose fasteners

or missing parts/components;

deterioration; deformation; corrosion;

or any other indications of damage/

problems that may affect the integrity

and operation of the product. If in doubt,

contact the manufacturer.

2. Lifeline:

The entire length of the lifeline

should be checked for signs of damage.

Inspect for cuts or broken strands,

unusual wearing patterns, corrosion,

kinks, or chemical damage.

3. Lowering and Raising Operation:

Apply

a light tension [50 lbs. (23kg) minimum]

on the cable lifeline, and:

a) Rotate the crank handle in a counter

clockwise direction to extend cable from

the unit (lower).

Note: When the cranking is stopped,

the friction brakes must securely

hold the load without the crank

handle rotating. Should this brake

malfunction, an independent

overspeed braking system will be

activated.

b) Rotate the crank handle clockwise to

return the cable to the unit (raise). There

should be a clicking noise heard while

the cable is being cranked into the unit.

4. Snap Hook:

Check the snap hook to be

sure that the gate operates freely, the

locking mechanism functions properly,

and the swivel rotates smoothly. The

gate should seat into the nose without

binding and should not be distorted

or obstructed. The gate spring should

exert sufficient force to firmly close

the gate. The locking mechanism must

prevent the gate from opening when the

gate is closed. Inspect the snap hook

for any signs of damage to the gate;

bent, cracked, or distorted components;

corrosion or pitted surfaces.

5. Anchorage Connection:

Make sure

the unit is properly anchored to the

mounting device and the push pins are

properly installed through the mounting

bracket. If the system is equipped with a

sheave and carabiner, check to ensure

the carabiner is properly seated and in

the locked position between the sheave

and anchorage point.

UNITS THAT DO NOT PASS INSPECTION

OR HAVE BEEN SUBJECTED TO THE

FORCES OF ARRESTING A FALL OR

AFFECTING A RESCUE MUST BE

REMOVED FROM SERVICE.

5.2 Maintenance

Basic care of all safety equipment will pro-

long the durable life of the unit and will con-

tribute toward the performance of its vital

safety function.

Servicing

Servicing of the Miller ManHandler

Hoist/Winch must only be carried out

by Miller Fall Protection or persons or

entities authorized in writing by Miller Fall

Protection. A record log of all servicing

and inspection dates for this device

must be maintained. Only original Miller

replacement parts are approved for use

in this device. Repairable devices must be

returned to our facilities or an approved

service center for physical inspection and

recertification whenever they do not pass

inspection or have been subjected to the

forces of arresting a fall or affecting a

rescue. Non-repairable devices that do not

pass inspection must be disposed of in a

manner to prevent inadvertent further use.

Contact your Miller distributor for a return

authorization number.

Cleaning and Storage

Periodically clean the exterior of the device

and wipe the lifeline using a damp cloth

and mild detergent. Towel dry. Store in a

clean, dry location when not in use.

The

lifeline should be fully retracted into the

device when not in use.