1 - 18

Fittings Specifications

TIGHTENING HYDRAULIC FITTINGS

Escaping fluid under pressure can penetrate the skin

causing serious injury. Relieve pressure before

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure. Keep hands and

body away from pin holes and nozzles which eject

fluids under high pressure. Use a piece of cardboard or

paper to search for leaks. DO NOT use your hand.

Failure to comply may result in personal injury.

1.

Inspect O-ring and seat for dirt or obvious defects.

2.

On angle fittings, back the locknut off until washer

bottoms out at top of groove.

3.

Hand-tighten fitting until backup washer or washer

face (if straight fitting) bottoms on face and O-ring is

seated.

4.

Position angle fittings by unscrewing no more than

one turn.

5.

Tighten straight fittings to torque shown in O-ring Fit-

ting Torque Chart below.

Torque values shown in both torque charts below are based on

lubricated connections (such as for reassembly).

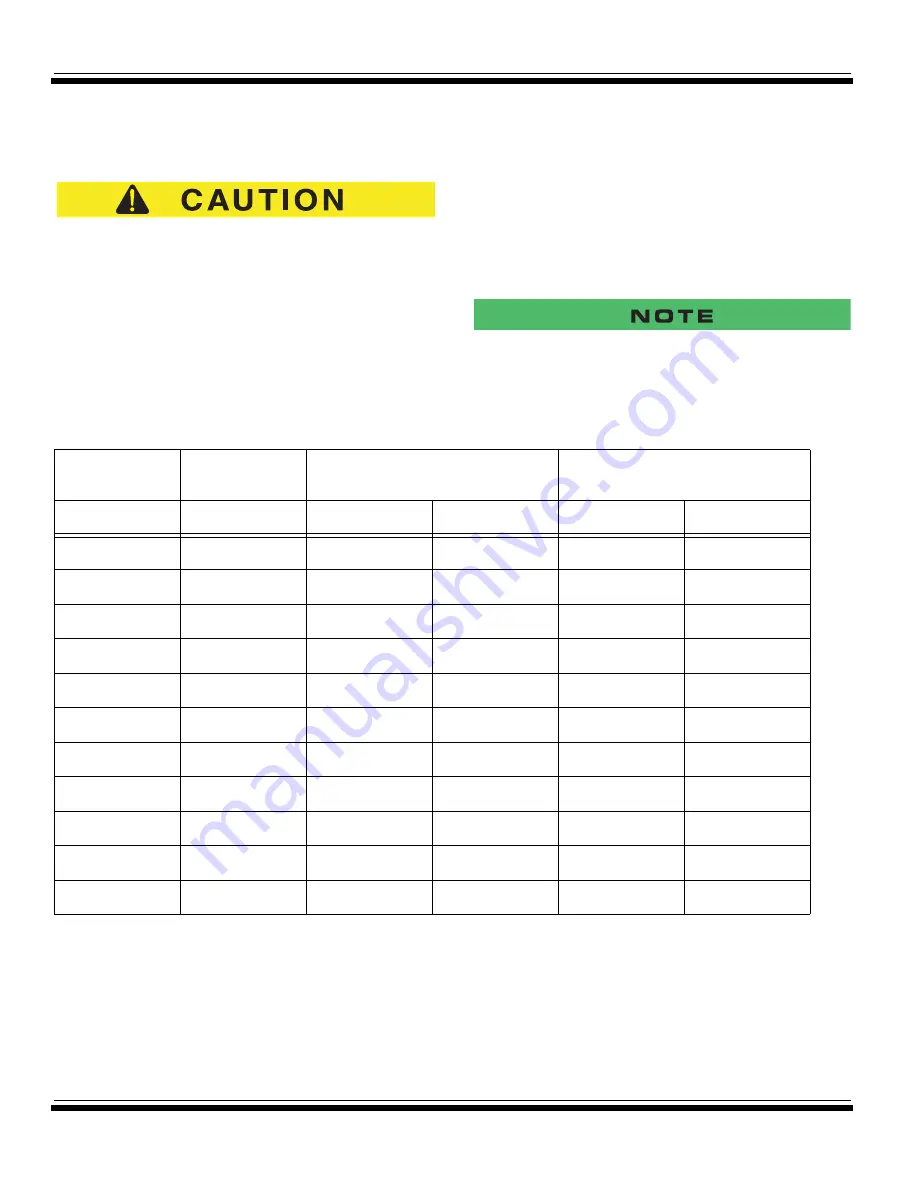

O-ring Fitting Torque Chart

Thread Size

Nut Size Across

Flats

Torque Value

Recommended Turns to Tighten

(after finger tightening)

in.

in.

N•m

ft-lb

Flats

Turns

3/8

1/2

8

6

2

1/3

7/16

9/16

12

9

2

1/3

1/2

5/8

16

12

2

1/3

9/16

11/16

24

18

2

1/3

3/4

7/8

46

34

2

1/3

7/8

1

62

46

1-1/2

1/4

1-1/16

1-1/4

102

75

1

1/6

1-3/16

1-3/8

122

90

1

1/6

1-5/16

1-1/2

142

105

3/4

1/8

1-5/8

1-7/8

190

140

3/4

1/8

1-7/8

2-1/8

217

160

1/2

1/12