OM-246 022 Page 9

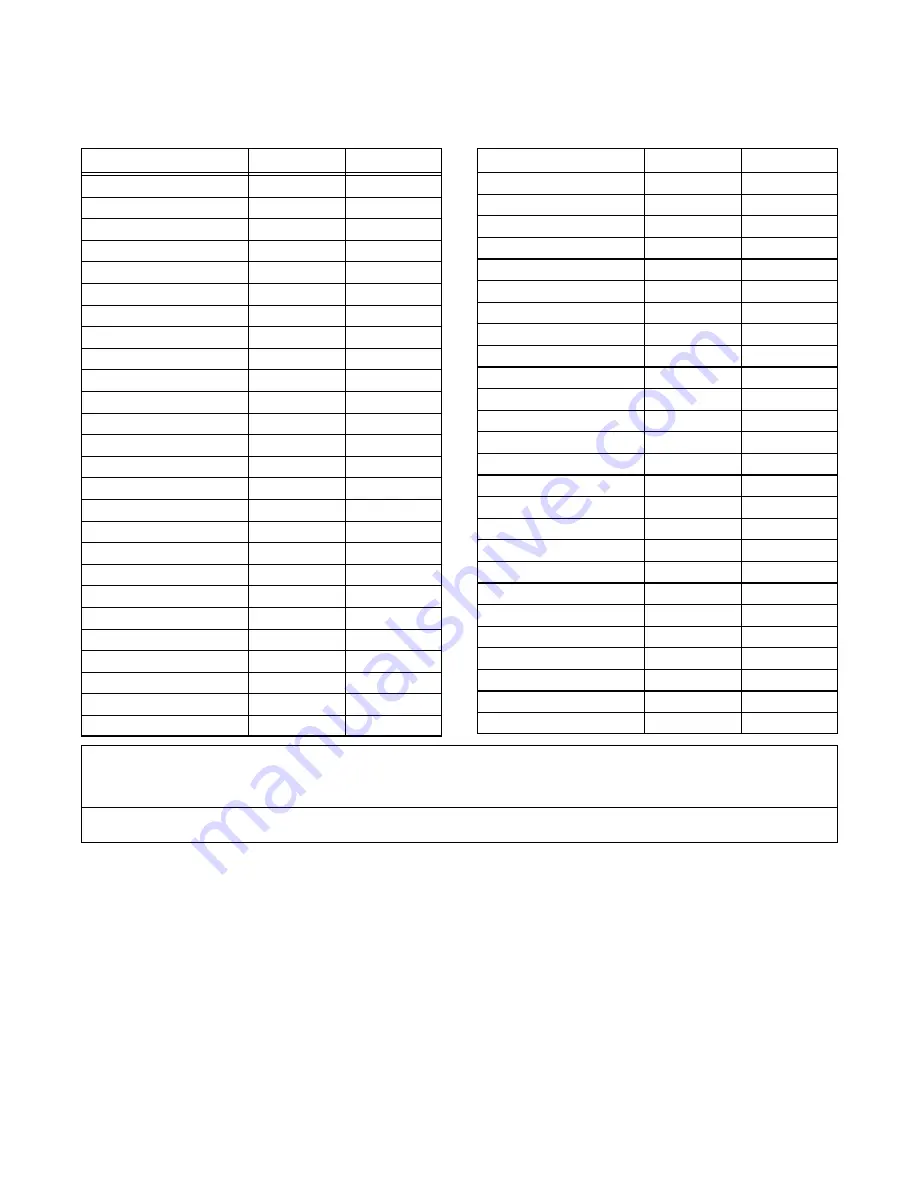

3-4.Compatibility Chart*

.

Compatibility was determined for current production models only. Number in () indicates function ability limiter. See below for explanation.

Machines not included in this list have not been tested.

Machine

Foot Control

Hand Control

Axcess

Series

No

No

Aerowave

Yes

Yes

Big Blue

Air Pak

Yes (5)

Yes (2, 5)

Big Blue

Turbo

Yes (5)

Yes (2, 5)

Big Blue

, Big 40

CC

No

No

Big Blue

, Big 40

CC/CV

Yes (5)

Yes (2, 5)

Big Blue

300 Pro

Yes

Yes

Big Blue

350 PipePro

Yes

Yes

Big Blue

400 Eco Pro

Yes

Yes

Blue Star

No

No

Bobcat

t

Series

No

No

CP-302

Yes (4)

Yes (4)

CST

t

280

Yes (3)

Yes (2, 3)

CST

t

280 Rack

Yes (3)

Yes (2, 3)

Delta-Fab

t

Yes

Yes

Deltaweld

Series

Yes

Yes

Dialarc

250

No

No

Dimension

t

Series

Yes

Yes

Diversion

t

165

No

No

Diversion

t

180

Yes (7)

Yes (2, 7)

Dynasty

200/350/700

Yes

Yes

Goldstar

Series

Yes

Yes

HF 251

No

No

Invision

t

MPA, MP, And P

Yes

Yes

Mark VI

t

Yes

Yes

Mark VIII-2

No

No

Machine

Foot Control

Hand Control

Maxstar

150 S

No

No

Maxstar

150 STL/STH

Yes (1, 8)

Yes (1, 8)

Maxstar

200 SD, DX, LX

Yes

Yes

Maxstar

200 STR

No

No

Maxstar

350/700

Yes

Yes

Miller Du-Op

Yes

Yes

Millermatic

(All)

No

No

PipePro

304

Yes (6)

Yes (6)

PipePro

450 RFC

No

No

Pipeworx

t

Yes (9)

Yes (10)

PRO

300

Yes

Yes

Renegade

t

180

No

No

Shopmate

t

300

Yes

Yes

SRH-444

No

No

Subarc DC 650, 1000

Yes

Yes

Summit Arc

t

1000, 1250

Yes

Yes

Syncrowave

200

Yes

Yes (2)

Syncrowave

250DX/350LX

Yes

Yes

Thunderbolt

No

No

Trailblazer

Series

No

Yes

Trailblazer

No

Yes

Wildcat

200

No

No

XMT

304/350

Yes

Yes

XMT

350 VS

No

No

XMT

350 VS Rack

No

No

XMT

Rack

Yes

Yes

(1) With Adapter 300 507, (2) Displays Percentage Only, (3) Only Controls Output Level - No Contactor Control, (4) Only Activates Contactor,

(5) Must Disconnect Diagnostic Board (See Section 3-14), (6) With Adapter 300 749 (7) With Adapter 300 688 (8) Remote Only Works In TIG

Mode (9) Prior to Serial Number MA470021G, Kit 300859 is required (kit includes PCB and #300429 foot control), (10) After Serial Number

MA470021G

*Not all applications are suitable for wireless communication. Rated range is approximate, and may vary depending on factors such as obstruc-

tions, frequency interference, transmission technology, and weather. The figures listed assumes ideal conditions are present.