PL-543

14

Replacement Procedure

To replace the bearings when they are worn follow these steps.

Removing the Bearings

1.

Remove the MD-256 cover

2.

Remove the wiring from the terminal block

3.

Remove the unit from its installation

4.

Unscrew the circuit board fixing screws

5.

Remove the circuit board and store in a static-free bag or equivalent “safe” area.

6.

Remove the first bearing’s C clip (part A) using retaining ring pliers

7.

Gently drift the unit’s shaft out of the housing. One bearing should come with the shaft

and one should remain in the housing.

8.

Pull the bearing off the shaft

9.

Drift out the bearing and rawhide seal (part F) from the housing

10. Clean the housing with a rag

Replacing the Bearings

1.

Warm the housing in hot water to expand the metal

2.

Remove from the water and completely dry with a clean rag

3.

Insert the rawhide seal (part F) into the housing

4.

Slide one of the new bearings (part D) into the housing. Ensure it fits snugly against

the end of the housing

5.

Slide the second bearing onto the unit’s shaft

6.

Gently drift the shaft back into place. It is in place when you can see the groove for the

C clip (part A). Do not damage the pin on the end of the shaft as that is required to turn

the encoder.

7.

Replace the C clip (part A)

8.

Replace the circuit board and ensure correct alignment of the rubber coupling and the

shaft pins.

9.

Replace the mounting screws for the circuit board

10. Reconnect to the installation

11. Rewire the terminal block

12. Replace the MD-256 cover

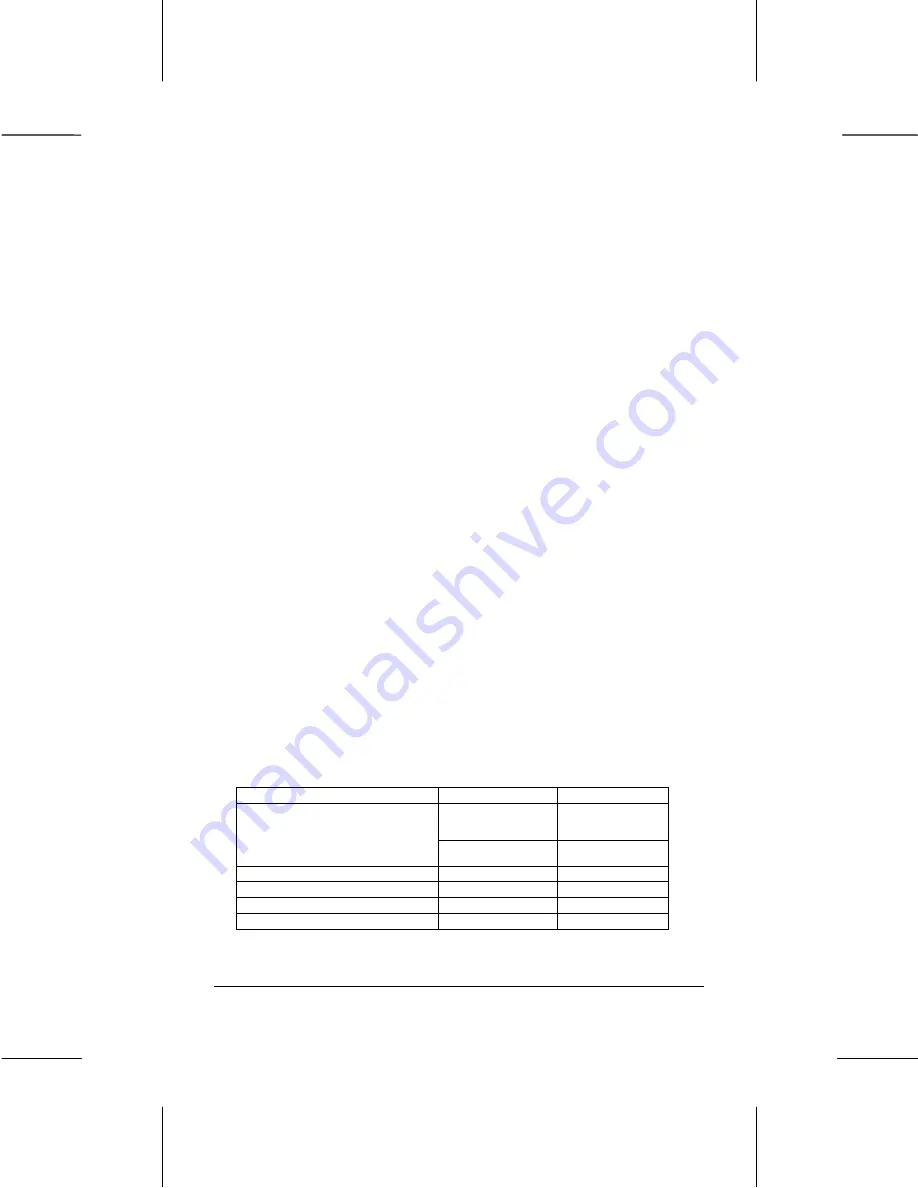

Replacement Parts

Part numbers and suppliers for the user-serviceable parts in the MD-256 are:

Part

Supplier

Part Number

Boston Bearings,

1623DC

Bearings (parts D)

Nice Bearings

16232RS

C Clip (part A)

True Arc

R3000-137

C Clip (parts C)

True Arc

R3100-62

Rubber Connector (part E)

Milltronics

24300051

Dust Seal (part F)

Chicago Seals

6141