Although the accepted tolerance for idler alignement is

±

0.8 mm (1/32"), the scale mounted idlers should

never be lower than the adjacent idlers. Establishing good idler alignment is the most important part of the

installation procedure. Scale accuracy is directly affected by alignment. Proper attention must be given here.

CALIBRATION

GENERAL

After the MMI-2 has been properly installed, calibration of the weighing system must be done in conjunction

with the integrator. Refer to the integrator instruction manual for programming and calibration. The

calibration is initially done using the supplied test load. Material tests are recommended to achieve maximum

accuracy.

TEST LOAD

The test load value for each MSI is the same and is given on the accompanying data sheet. The value is to

be entered into the dedicated programming parameter of the integrator, in kilograms per meter or pounds per

feet. An equal number and mass of weights must be applied to each suspension during the span calibration

function.

If the actual idler spacing differs from that recorded on the design data sheet, the test load must be

recalculated as follows. Failure to do so will cause the design test load value to be in error.

test load =

total weight of all test weights per MSI kg

lb

idler spacing

m

ft

ZERO

Perform the zero calibration as described in the Calibration section of the integrator manual.

SPAN

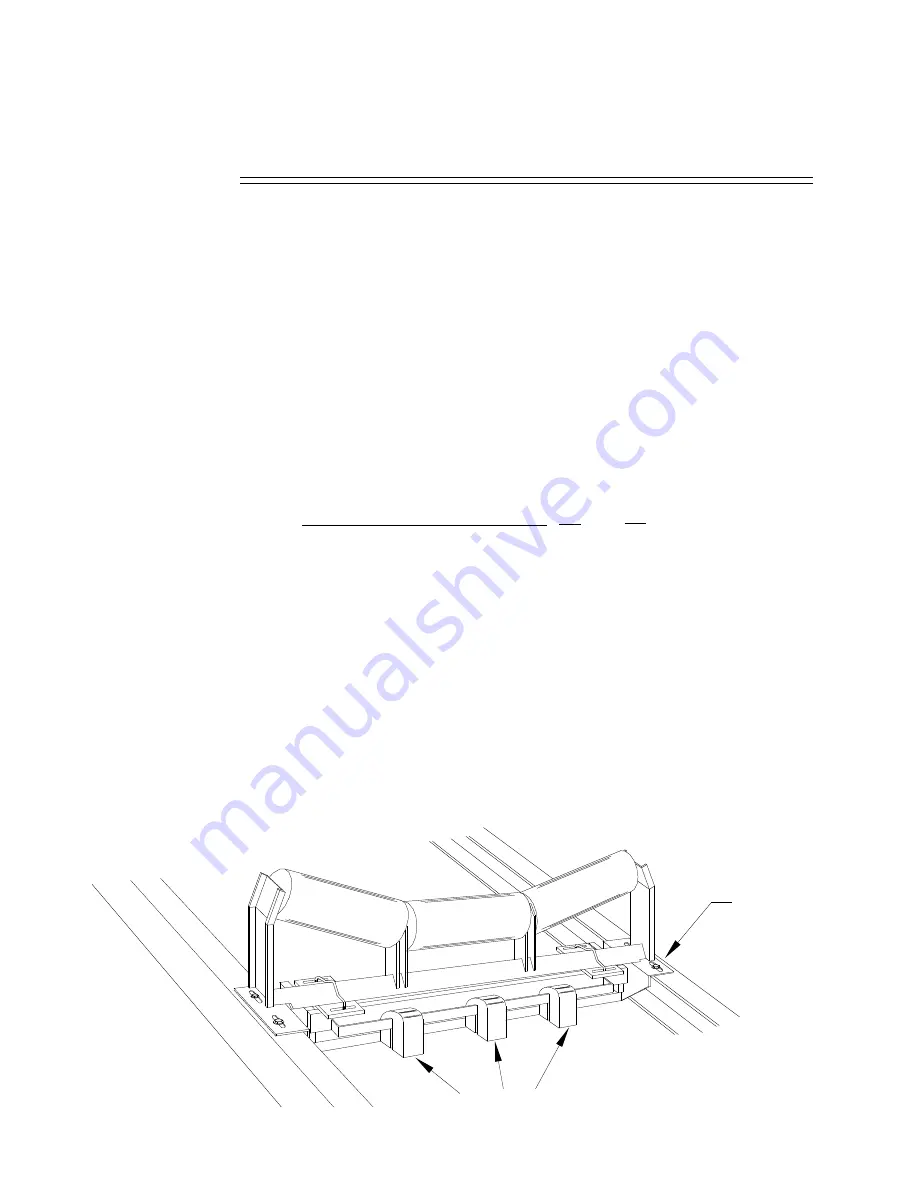

The test load used in the calibration procedure is the two sets of test weights ( 1 to 12 ) supplied, one for each

MSI suspension.

Place each set of the test weights onto the calibration weight bar of the respective MSI as shown.

Perform the span calibration as described in the Calibration section of the integrator instruction manual.

After the span calibration has been completed, remove the test load and store it.

( ) ( )

OR

test weight(s)

MSI

PL-327

8