INSTALLATION

PREAMBLE

The MMI-2 is shipped from the factory, attached to a frame for protection. Each MSI weighbridge must be

removed from its shipping frame and inspected for physical damage.

Insure that the conveyor design meets the installation requirements for the Milltronics MMI-2 scale. The

conveyor stringers must be rigid, straight, parallel to and square with the belt line in the area of the scale

installation. The idlers to be used on the scale and at least the next two approach and retreat idlers must be

of the same style and manufacture and in good condition.

Prepare the site in accordance with the Milltronics drawing(s) provided or by reference to Milltronics

instruction manual PL-328, Applications Guidelines.

WELDING

Extreme caution should be used when arc welding in the area of the belt scale. Insure that no welding current

can flow through the belt scale. Welding currents through the scale are sufficient to functionally destroy the

load cells.

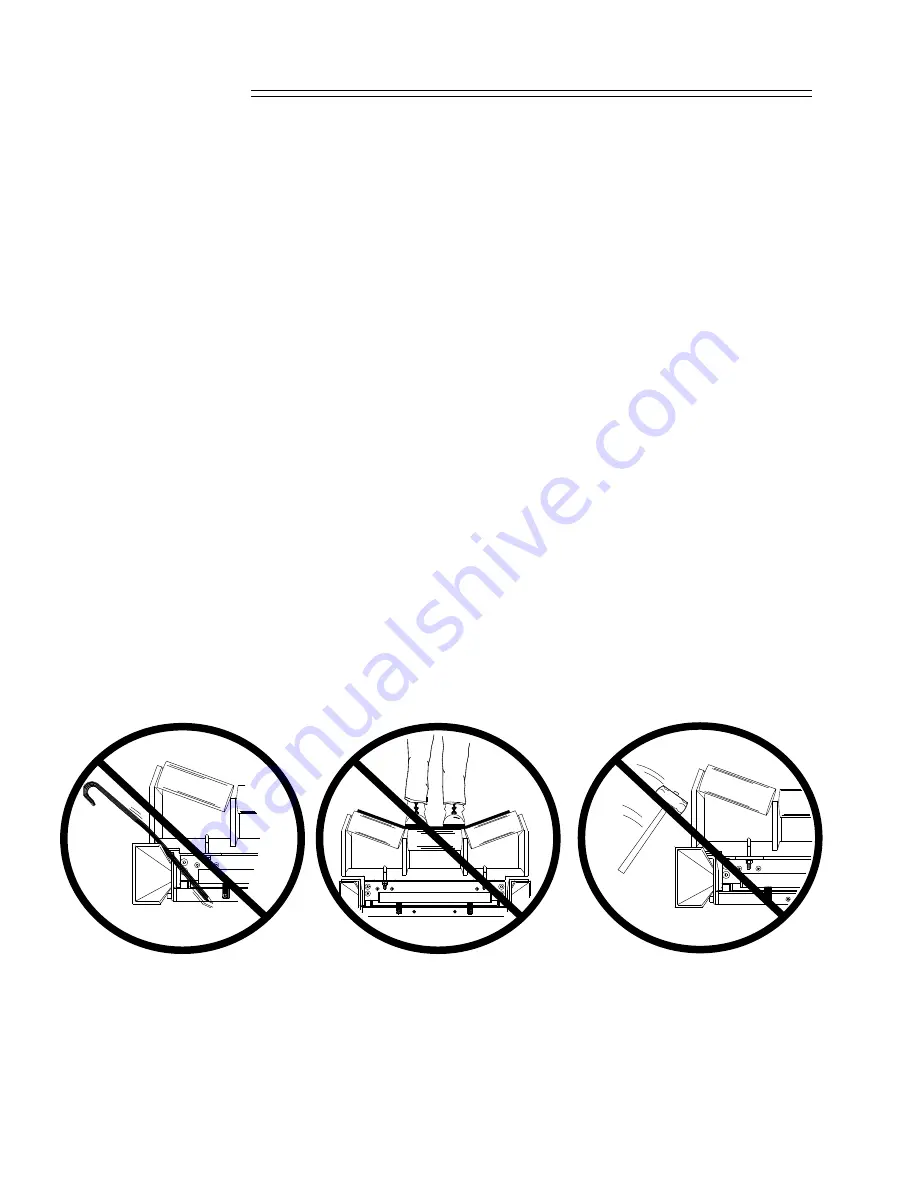

LOAD CELL HANDLING

The load cell can tolerate very little negative displacement, otherwise the load cell will be functionally destroyed.

When handling the individual MSI’s install both shipping stops to their vertical position to protect the load cells.

Do not lift the MSI’s by the weighing assembly or subject it to shock from blows of a hammer when trying to

position it.

DO NOT STAND OR WALK ON THE SCALE.

OVERLOADING, SHOCK AND TWISTING OF THE SCALE CAN ALL

FUNCTIONALLY DESTROY THE LOAD CELLS.

PL-327

4