7ML19981CR01

Milltronics Weight Lifter MWL – Instruction Manual

Page 19

Maintenance Procedures

Removing material accumulation

To ensure that the belt scale will provide optimal accuracy, periodically inspect the area

around the calibration weights and remove any material build-up.

The calibration weights must remain consistent to calibrate the scale correctly. If material

accumulates on top of them, the added weight will cause the calibration procedure to

produce poor results. The top surface of the calibration-weight supports must also be kept

clean for the scale to produce accurate results.

Material should not accumulate inside the crank body housings under normal operating

conditions, but it is a good idea to inspect them periodically.

1.

Remove any material build-up from the top of the calibration weights.

2.

Remove any material build-up from the top surface of the calibration-weight

supports between the calibration weights and the conveyor scale.

3.

Check inside the MWL crank body and inspect the worm gear drive: if material has

accumulated here, remove it with an air stream or other suitable device.

Greasing

On both crank bodies, the teeth of the drive plate are greased at the factory. They should

not require further greasing for a number of operations, depending on operating

conditions. Inspect the drive plate periodically, but apply grease only when it is required.

You may need to remove the bushed end-plates temporarily, to gain access to the teeth

and worm gear.

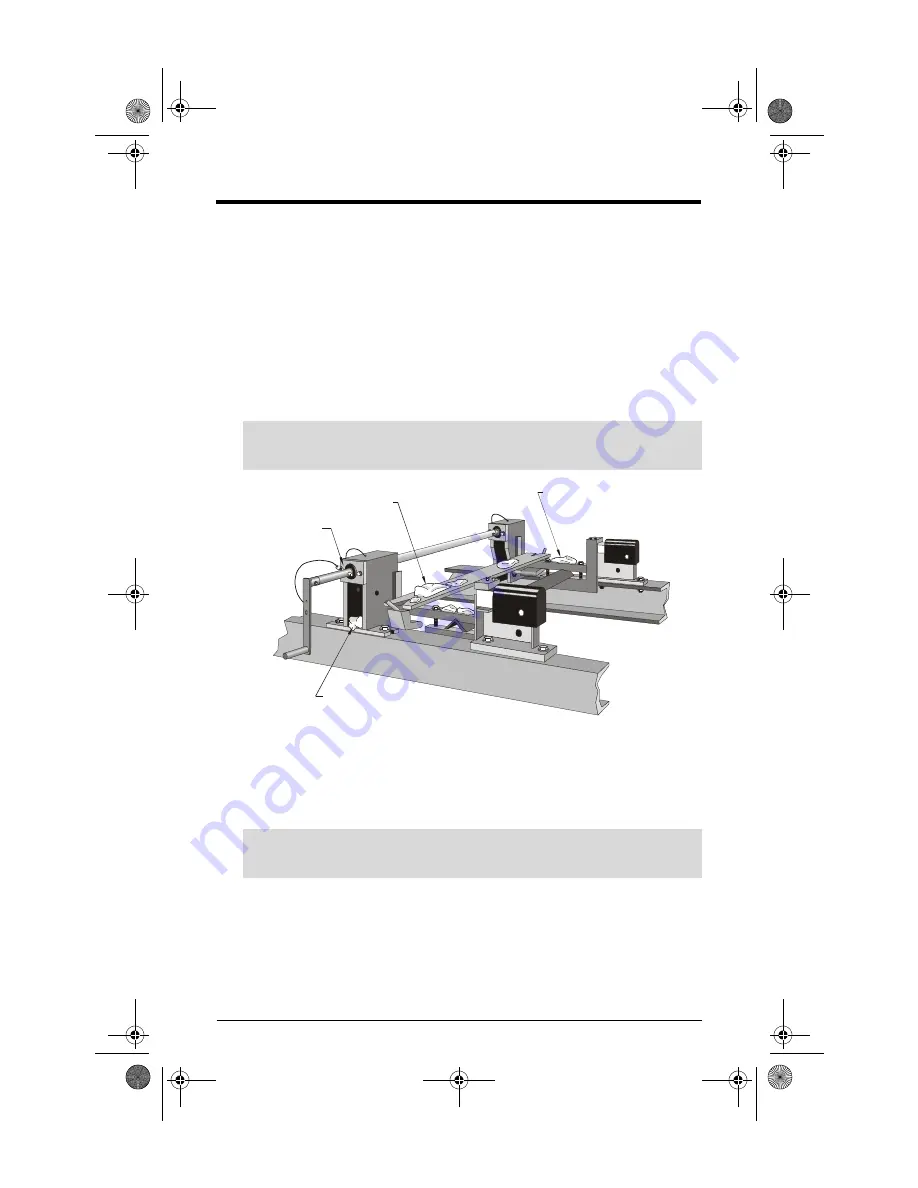

Note:

Before starting a calibration procedure, be sure to check that there is no

material accumulation in the three areas described below:

2. Top surface of calibration-

weight support

3. Inside crank body

1. Top surface of

calibration weights

(Bushed

end-plate)

Note:

The worm gear and notched plate are normally not accessible to the human

hand: do not force any foreign matter into the area during operation.

MWL48all.fm Page 19 Tuesday, June 12, 2001 8:23 AM