SEVERE MACHINE DAMAGE—Severe machine damage can result if the low speed drive

engages during or at the end of extract.

Immediately lock OFF and tag out power at the wall disconnect if any of the following occur:

☞

The machine makes a sound like skidding automobile tires as it comes out of extract;

☞

The wash or drain clutch does not disengage or prematurely engages during extract;

☞

The wash, drain, extract, or main drive belts jump off at the start of, during, or at the end

of extract;

☞

Strange sounds occur during extract.

☞

DO NOT permit the machine to operate until the cause is found and remedied.

Ë

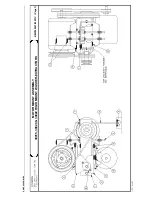

How the Centrifugal Switch Works

The centrifugal switch (used on Mark II machines) opens at speeds above drain. After E2 terminates, the

switch closes as soon as the cylinder slows sufficiently, enabling the controller to engage the wash clutch.

Ê

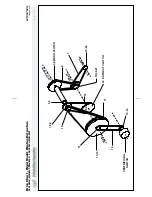

How the Machine Reverses

The wash/E1 motor periodically stops and reverses direction during washing and rinsing. Machines are

equipped with either single-phase or three-phase motors, each using a different method to reverse rotation. Two

relays (CRWAC and CRWAA) operate to change the cylinder direction. These relays are actuated so that only one

operates at a time. CRWAC causes clockwise rotation, CRWAA causes counterclockwise rotation.

Ë

Cylinder Reversal for Single-Phase Machines

—Rotation of single-phase motors is selected by

changing the polarity of the start winding. Relays CRWAC and CRWAA perform this action automatically.

Ë

Cylinder Reversal for Three-Phase Machines

—Rotation of three-phase motors is selected by ex-

changing two of three phased leads. Relays CRWAC and CRWAA automatically swap leads through a switching

process, thus changing rotational direction. There is a brief dwell period (generally less than three seconds) during

each change of direction. The cylinder is stationary during this time.

B

Summary of Contents for 30015

Page 6: ......

Page 8: ......

Page 10: ......

Page 19: ...Section 1 Service and Maintenance ...

Page 51: ...Section 2 Drive Assemblies ...

Page 59: ...BMP950003 95107V Page 1 MOTOR MOUNT 30015 30020 S4A S4G S4J S4T ...

Page 68: ......

Page 69: ...Section 3 Bearing Assemblies ...

Page 72: ...BMP910032 96141V Page 1 MAIN BEARING ASSEMBLY 30015C4x M4x K5x S5x ...

Page 74: ...BMP910033 96141V Page 1 MAIN BEARING ASSEMBLY ...

Page 76: ...BMP910034 95116V Page 1 MAIN BEARING ASSEMBLY 30015M6x ...

Page 80: ...BMP910035 93251V Page 1 JACKSHAFT ASSEMBLY 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 82: ......

Page 83: ...Section 4 Shell and Door Assemblies ...

Page 86: ...BMP920009 94491V Page 1 DOOR ASSEMBLY 30015 30020 RIGID MOUNT WASHER EXTRACTORS ...

Page 90: ......

Page 91: ...Section 5 Control and Sensing Devices ...

Page 100: ...BMP920010 97281V Page 1 COIN ASSEMBLY INSTALLATION 240V 30015 30020 30022 COIN MACHINES ...

Page 105: ...Section 6 Chemical Supply Devices ...

Page 113: ...Section 7 Water and Steam Piping and Assemblies ...

Page 114: ...ISOMETRIC SYMBOLS STANDARD SYMBOLS BMP920008 93027V Page 1 SCHEMATIC SYMBOLS KEY ...

Page 132: ...BMP920021 93251V Page 1 STEAM INSTALLATION 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 138: ...BMP920017 93251V Page 1 ELECTRIC DRAIN VALVE 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...