MSSM0709BE/9273BV (1 of 1)

È

JACKSHAFT BEARING REPLACEMENT

Ê

Removing the Jackshaft

ELECTROCUTION HAZARD—High voltage is present inside electric boxes, mo-

tors, and many other components. Power switches on machine control panels

disable only control circuit power in certain boxes. You can be killed or seri-

ously injured on contact with high voltage.

☞

Lock OFF and tag out power at the wall disconnect before servicing.

Dual motor drive 30015, 30020, and 30022 machines are equipped with jackshafts. Replace worn bearings

as described below.

See “JACKSHAFT ASSEMBLY” (see Table of Contents) during the following procedures:

1. With the power locked OFF, remove the top console cover by prying out the four plugs and unscrewing the

four bolts. Remove the rear belt guard.

2. Loosen and remove the belts from the jackshaft. Remove the straight bore pulley, electric clutch and coil from

the jackshaft (for further information see “DRIVE TRAIN SERVICE” in the Table of Contents).

3. Remove the four jackshaft mounting screws.

Ê

Replacing the Bearing

NOTE: Provide enough clearance around the bottom of the hous-

ing (FIGURE 1) as the bearing will come out with the shaft.

1. Remove and discard the shaft clip and place the assembly in a

press with the tapered shaft end pointing up as shown in FIGURE

1. Press the shaft down. When the lower bearing clears the hous-

ing, the shaft will drop out with the lower bearing remaining on

the shaft.

2. Place the shaft in the press and remove the bearing from the shaft.

Remove the outer retaining ring from the housing and discard.

Place the housing in the press with the bearing facing downward,

then press the bearing out. Remove the inner retaining ring and

discard all retaining rings.

3. Thoroughly clean all parts with solvent. The bearing housing

and shaft must be absolutely clean and free of dirt and ad-

hesives.

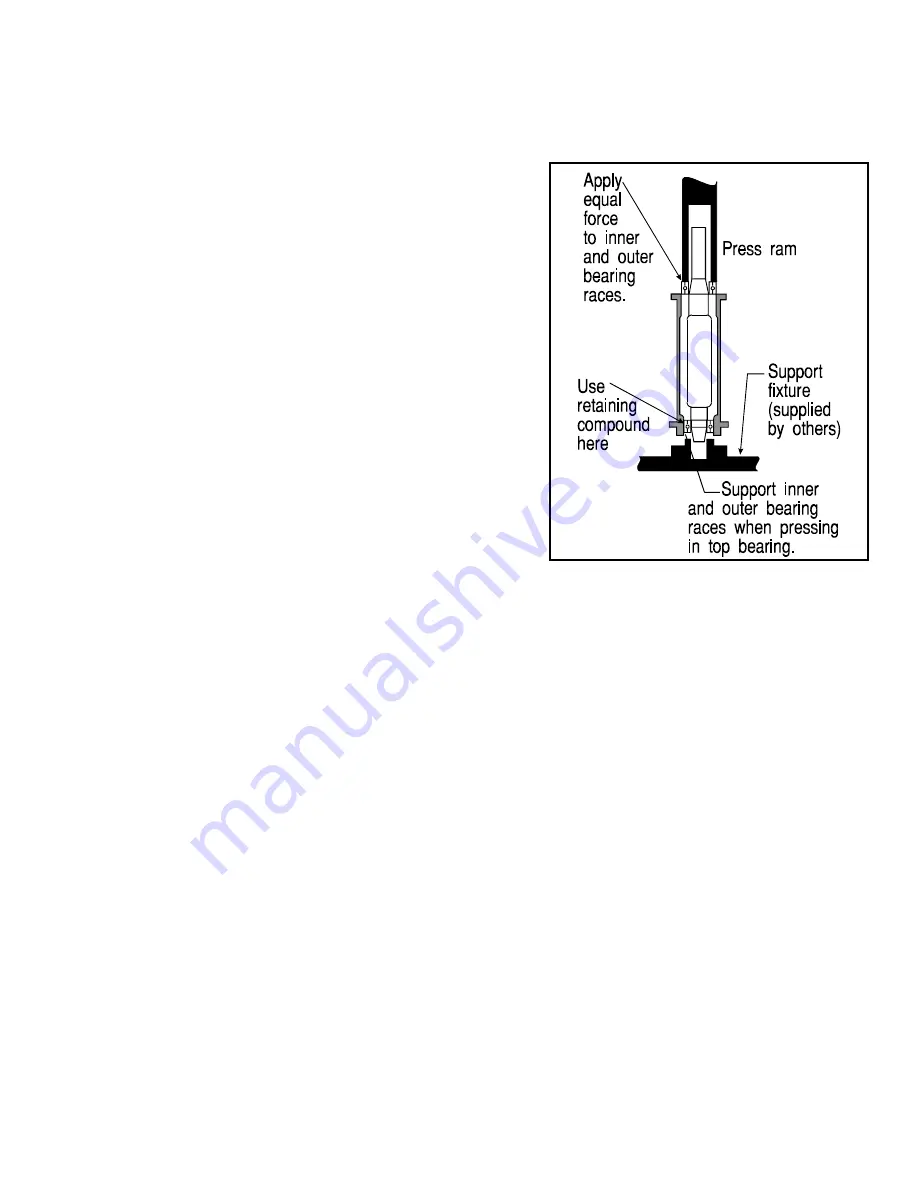

4. Install a new inner retaining ring inside the housing and apply a

small amount of retaining compound (Loctite 271 or similar)

around the bearing seating surface of the bearing housing as

shown in FIGURE 2. Press the new bearing in the housing, ap-

plying equal force to the inner and outer bearing races. Install a

new outer retaining ring in the housing.

5. Slide the other new bearing onto the shaft and place the shaft in-

side the housing with the tapered end into the installed bearing.

Place the assembly under the press with the housing completely

supported by the inner and outer race of the bearing as shown

in FIGURE 2. Simultaneously press the bearing onto the shaft

and into the housing until the bearing bottoms out, applying

equal force to both inner and outer bearing races. Install a new

shaft clip (tapered end only).

Ê

Installing the Jackshaft

1. Replace the jackshaft and all related components in reverse order

of disassembly.

2. Align pulleys and set belt tension as explained in “DRIVE TRAIN SERVICE”.

Î

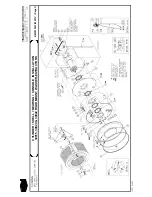

FIGURE 1

(MSSM0709BE)

Î

Removing Jackshaft

Bearings

Î

FIGURE 2

(MSSM0709BE)

Î

Replacing Jackshaft

Bearings

B

Summary of Contents for 30015

Page 6: ......

Page 8: ......

Page 10: ......

Page 19: ...Section 1 Service and Maintenance ...

Page 51: ...Section 2 Drive Assemblies ...

Page 59: ...BMP950003 95107V Page 1 MOTOR MOUNT 30015 30020 S4A S4G S4J S4T ...

Page 68: ......

Page 69: ...Section 3 Bearing Assemblies ...

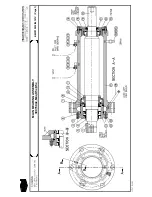

Page 72: ...BMP910032 96141V Page 1 MAIN BEARING ASSEMBLY 30015C4x M4x K5x S5x ...

Page 74: ...BMP910033 96141V Page 1 MAIN BEARING ASSEMBLY ...

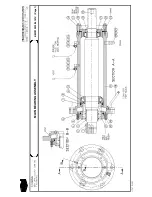

Page 76: ...BMP910034 95116V Page 1 MAIN BEARING ASSEMBLY 30015M6x ...

Page 80: ...BMP910035 93251V Page 1 JACKSHAFT ASSEMBLY 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 82: ......

Page 83: ...Section 4 Shell and Door Assemblies ...

Page 86: ...BMP920009 94491V Page 1 DOOR ASSEMBLY 30015 30020 RIGID MOUNT WASHER EXTRACTORS ...

Page 90: ......

Page 91: ...Section 5 Control and Sensing Devices ...

Page 100: ...BMP920010 97281V Page 1 COIN ASSEMBLY INSTALLATION 240V 30015 30020 30022 COIN MACHINES ...

Page 105: ...Section 6 Chemical Supply Devices ...

Page 113: ...Section 7 Water and Steam Piping and Assemblies ...

Page 114: ...ISOMETRIC SYMBOLS STANDARD SYMBOLS BMP920008 93027V Page 1 SCHEMATIC SYMBOLS KEY ...

Page 132: ...BMP920021 93251V Page 1 STEAM INSTALLATION 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 138: ...BMP920017 93251V Page 1 ELECTRIC DRAIN VALVE 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...