MSSM0711AE/9272BV (1 of 2)

È

REPLACING AND ADJUSTING

THE POWER SUPPLY

In the unlikely event of a power supply failure, see the

replacement and adjustment instructions for the machine in

this section. Use a high quality digital voltmeter (Fluke model

77 or similar) for measuring voltages.

Ê

For C4A, M4A, System 7

®

,

and E-P Plus

®

Models

ELECTROCUTION HAZARD—

High voltage is present inside

electric boxes, motors, and many

other components. Power switch-

es on machine disable only control circuit

power in certain boxes. You can be killed or

seriously injured on contact with high voltage.

☞

Lock OFF and tag out power at the wall

disconnect before servicing.

Ë

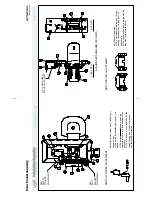

Replacing the Power Supply

—See FIGURE 1 during the following procedures:

1. Remove the console top and belt guard.

2. Remove the power supply and processor board covers.

3. After replacing the power supply, see “Adjusting Output Voltage” in this section.

Ë

Adjusting Output Voltage

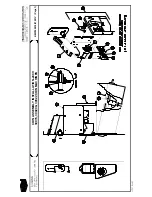

CRUSH AND ENTANGLE HAZARD—Machine power is ON and covers are re-

moved for the following procedures. Rotating machinery can entangle and

crush body parts.

☞

Before turning power ON, open shell door to prevent machine rotation.

ELECTROCUTION HAZARD—Machine power is ON and covers are removed for

the following procedures. You can be killed or severely injured by contact with

exposed components which are energized at 120VAC or higher.

☞

DO NOT touch any components while adjusting output voltage.

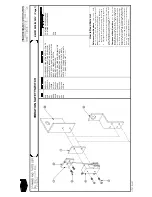

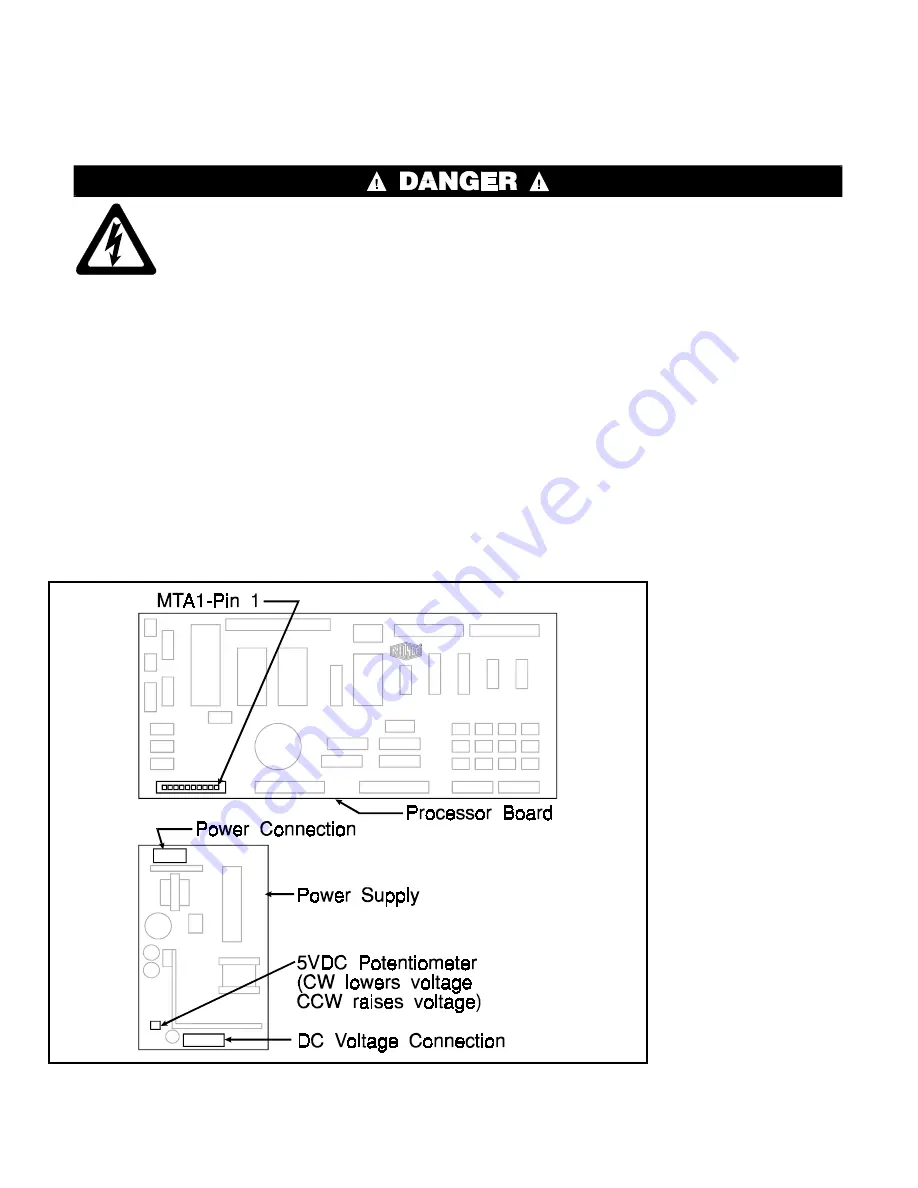

See FIGURE 2 during the following procedures:

1. Restore power at the wall disconnect.

2. Locate connector MTA1 on the processor board. Touch the negative meter probe to the rear of pin 9

(ground connection).

3. Touch the positive meter probe to the rear of pin 3 (+5VDC).

Voltage must be between 4.95 and 5.06VDC. If not, turn the 5VDC potentiometer slowly (clockwise to

lower, counterclockwise to raise) until the meter displays the correct value. The microprocessor will not

operate if this voltage is not within tolerance. After setting 5VDC output voltage, with the negative meter

probe still touching the rear of pin 9 (ground connection):

1. Touch the positive meter

probe to the rear of pin 5.

The voltage must be between

+11.5 to +13.5VDC .

2. Touch the positive meter

probe to the rear of pin 7.

The voltage must be between

-11.5 to -13.5VDC.

Power Supply Cover Processor Board Cover

Î

FIGURE 1

(MSSM0711AE)

Î

Location of Power Supply and

Processor Board ( E-P Plus

®

shown)

Î

FIGURE 2

(MSSM0711AE)

Î

Location of Output Voltage Potentiometer and Connector MTA1

B

Summary of Contents for 30015

Page 6: ......

Page 8: ......

Page 10: ......

Page 19: ...Section 1 Service and Maintenance ...

Page 51: ...Section 2 Drive Assemblies ...

Page 59: ...BMP950003 95107V Page 1 MOTOR MOUNT 30015 30020 S4A S4G S4J S4T ...

Page 68: ......

Page 69: ...Section 3 Bearing Assemblies ...

Page 72: ...BMP910032 96141V Page 1 MAIN BEARING ASSEMBLY 30015C4x M4x K5x S5x ...

Page 74: ...BMP910033 96141V Page 1 MAIN BEARING ASSEMBLY ...

Page 76: ...BMP910034 95116V Page 1 MAIN BEARING ASSEMBLY 30015M6x ...

Page 80: ...BMP910035 93251V Page 1 JACKSHAFT ASSEMBLY 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 82: ......

Page 83: ...Section 4 Shell and Door Assemblies ...

Page 86: ...BMP920009 94491V Page 1 DOOR ASSEMBLY 30015 30020 RIGID MOUNT WASHER EXTRACTORS ...

Page 90: ......

Page 91: ...Section 5 Control and Sensing Devices ...

Page 100: ...BMP920010 97281V Page 1 COIN ASSEMBLY INSTALLATION 240V 30015 30020 30022 COIN MACHINES ...

Page 105: ...Section 6 Chemical Supply Devices ...

Page 113: ...Section 7 Water and Steam Piping and Assemblies ...

Page 114: ...ISOMETRIC SYMBOLS STANDARD SYMBOLS BMP920008 93027V Page 1 SCHEMATIC SYMBOLS KEY ...

Page 132: ...BMP920021 93251V Page 1 STEAM INSTALLATION 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...

Page 138: ...BMP920017 93251V Page 1 ELECTRIC DRAIN VALVE 30015 30020 30022 RIGID MOUNT WASHER EXTRACTORS ...