22

Pellerin Milnor Corporation

•

Look for belt damage as shown in the figure above.

•

Look for worn pulleys as shown in the figure above.

With the machine in operation—Do not touch the machine.

Look and listen:

•

A belt can have some vibration and not cause damage. It is necessary to correct this condition

only if the vibration is large.

•

A belt must have sufficient tension that there is no slippage on the pulley during operation. If

slippage occurs, you can usually tell from the noise.

About Component Replacement and Tension Adjustment

—Correct adjustment is very impor-

tant to the service life of components and operation of the machine. Your Milnor

®

dealer can do

this work. If you know how to do this work (for example, correctly align belts and pulleys), and

you want to do it, speak to your dealer or Milnor

®

for part numbers. Replace worn components

before you make tension adjustments.

•

Machines that use rods with full threads and nuts to hold the position of the motor base—Turn

the nuts on the rods as necessary to adjust tension. Tighten the nuts.

•

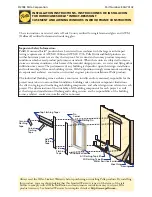

Machines that use a spring to hold tension on the motor base—Use the belt tension sleeve

supplied with the machine. Put the sleeve on the rod that the spring is attached to or remove

the sleeve to increase or decrease tension (see the figure below). Replace the spring if

necessary.

Figure 8.

How to Adjust Belt Tension On a Machine That Uses Spring Tension

Views of Motor Base

Legend

A...

Motor base with no tension sleeve

B...

Motor base with tension sleeve

added

1...

Shaft collar - one of two

2...

Motor mount shaft

3...

Tension sleeve - supplied with

machine

Summary of Contents for 30015T6X

Page 2: ......

Page 4: ......

Page 5: ...English 1 ...

Page 6: ......

Page 10: ...Pellerin Milnor Corporation iii Table 10 Where to Put Marks On a Calendar 21 Contents ...