MSSMA408BE/9273BV (1 of 1)

È

VIBRATION SAFETY SWITCH ADJUSTMENTS

Ë

What the Vibration Safety Switch Does

The vibration safety switch pictured below is an important safety feature. If properly adjusted, the switch will

momentarily actuate as a result of repeated machine movement caused by an out-of-balance condition. Table A

below illustrates the effect of the vibration safety switch actuation.

Ï

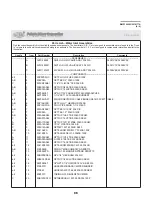

Table A—Effect of Tripping Vibration Safety Switch

Machine Model

Function of Vibration Safety Switch

30015, 30020, and 30022

Disables high speed extract

All microprocessor-controlled washer-extractors not

listed above, and all dye machines

De-energizes three-wire relay, effectively

terminating machine operation

Ê

Adjustments

When the machine leaves Milnor

®

, the actuator arm is

tie-wrapped to prevent damage (except on 30015, 30020, and

30022 models). This tie wrap must be removed after the

machine is set into position but before the machine is op-

erated.

Adjustment of this switch from the factory setting is not

recommended; however, it should be checked for proper

functioning and adjusted if its proper setting is lost.

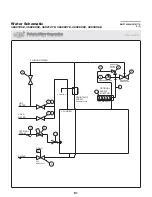

As shown at right in FIGURE 1, the unit consists of a

sensitive micro-switch with an extended actuating arm sup-

porting an eccentric weight. The weight may be adjusted by

moving it up and down on the arm and by rotating it on the

arm. In addition, the micro-switch itself may be tilted from

side to side.

The sensitivity of the switch increases as the eccen-

tricweight is raised on the actuating arm and de-

creases as the weight is lowered.

The unit should be adjusted so that the actuating arm

will always reset by itself, this being accomplished by rotat-

ing either the switch or the weight to give just enough bias to

cause the switch to reset. Check the adjustment by moving the

arm to the left then slowly releasing it. Make sure the micro-

switch clicks when the arm is slowly released, thus indicating

that it has reset. In the released position the arm should rest lightly but definitely against the stop on the micro-switch

case that prevents any further arm movement to the left.

For machines with rigid mounted shells, where the machine is bolted to a very substantial foundation, very

little machine movement will occur for a given degree of out-of-balance. Under such conditions it may be better to

adjust the switch to be very sensitive. With less substantial foundations (e.g., ones where the sub-soil is mushy or

springy or otherwise not as desirable), considerably greater machine movement will occur for a given degree of

out-of-balance, in which case a less sensitive vibration switch setting may be indicated.

Î

FIGURE 1

(MSSMA408BE)

Î

Vibration Switch

B

B

B

B

95

Summary of Contents for 36021V5Z

Page 2: ......

Page 35: ...Service and Maintenance 1 31 ...

Page 44: ......

Page 45: ...Drive Assemblies 2 41 ...

Page 52: ......

Page 53: ...Bearing Assemblies 3 49 ...

Page 65: ...20 Inch Door Assemblies after 8 2016 4 61 ...

Page 75: ...Chemical and Supply Devices 5 71 ...

Page 83: ...Water Piping Assemblies 6 79 ...

Page 96: ......